Molds, Hot Runner Systems, Digital Technologies Highlight Sustainable Production

The Molding Solutions network at K Show displays Männer, Foboha, Synventive, Thermoplay, Priamus, Gammaflux and other external partners and their new or proven technologies for molding and moldmaking.

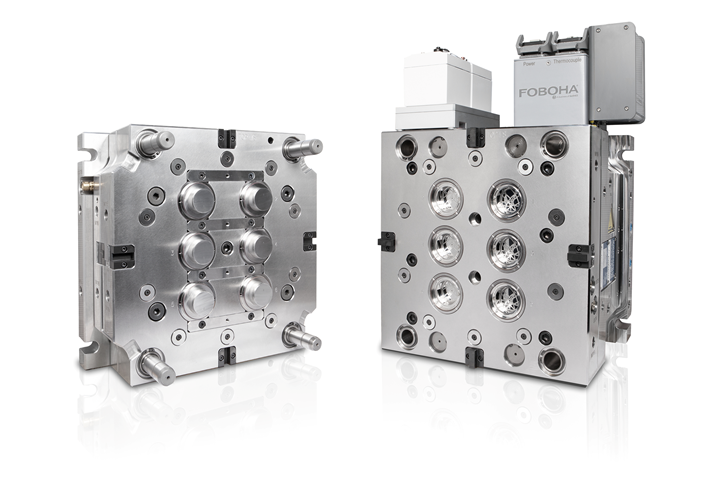

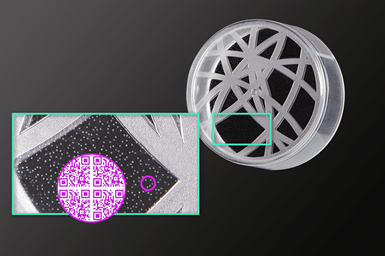

Digital watermark technology: Six-cavity Foboha mold with laser engraved inserts to apply the digital watermark. Photo Credit, all images: Foboha

The Molding Solutions network at K 2022 — a business within Barnes — has bundled the expertise of its members, Männer, Foboha, Synventive, Thermoplay, Priamus and Gammaflux, which are highlighting mold and hot runner technology and controls.

At its own booth, the Molding Solutions network is showing how digitization helps simplify recycling of packaging materials. A digital watermark is given to packaging made of a certified bio-based material, for example, so that recycling centers can automate the separation of these digitally marked products in the waste stream — mold inserts are laser engraved to apply the digital watermark onto the mold, which then applies it to the part when molded.

moldMIND, said to be the “digital cockpit” of the injection mold, is a recording system that documents relevant process data and events of an injection mold in real time throughout its entire life cycle. The intelligent monitoring system detects problems quickly to minimize downtime. The data can be accessed directly on the device or in the Barnes Connectia Cloud, which celebrates its premiere at the K Show.

Synventive showcases a new electric valve gate, the compact eGate Sync. Alongside a plug-and-play installation and simple user interface, quality is said to be improved by increasing shot-to-shot consistency with significant energy savings.

Another technology, the Synventive and Männer hot runner configurator, enables 3D data generation for 2-, 4- or 8-drop hot runner systems through the application check, which includes a follow-up with an application engineer for applications outside of guidelines. The step-by-step configuration can draw on a material database of more than 12,000 resins.

Männer is also expanding its Packaging and Slimline product range with additional valve gate nozzles. The Packaging range for high-speed molds is complemented by the MCN-EP, with a small diameter and permanently centered valve gate pin. The design of the nozzle tip facilitates high-precision gating and enables the correction of tip protrusion without reworking (patent pending). Like the MCN 8 and MCN 6.5, Männer says the new MCN 5 valve gate nozzle from the Slimline series is said to be ideal for tight installation conditions in high-cavity molds. A 3D-printed manifold designed using artificial intelligence (AI) is used to show how the design of flow bore helps a non-symmetrical six-drop hot runner system achieve optimized balancing.

Thermoplay has added two nozzles to its TFS series — the open nozzle series for side injection — for larger part volumes. Additional Thermoplay innovation is aimed at special applications. For example, Thermoplay has created nozzles for a 45° gate to produce conical parts as well as multi-tip nozzles for small parts that are gated with several gating points.

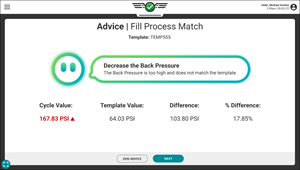

The Fillcontrol process monitoring system from Priamus is said to use digital intelligence to identify and correct material fluctuations that contribute to decreased quality through dynamic process control. This is achieved by adjusting the manipulated variables of pressure and temperature signals.

Gammaflux rounds off the portfolio with its hot runner temperature control technology, particularly the G24, with its in-house Triangulated Control Technology and up to 192 zones.

The Molding Solutions network is also displaying an additional five molds and several hot runner systems, as well as temperature controllers and process control systems at external partner booths.

KraussMaffei demonstrates how material can run through several product life cycles. Medical consumables are produced from polypropylene (PP) in Männer's 96-cavity mold, after which the material is granulated and fed to the production of automotive parts.

Pipette tips are manufactured and removed via Netstal’s turnkey system consisting of a 64-cavity pipette tip mold with hot runner from Männer, a Netstal Elion 2800-870 and high-speed automation from Micro Automation (MA).

Yushin relies entirely on lateral demolding robots. Blister packs are produced in a 16-cavity Männer mold and removed laterally, in a Netstal Elion 800, ultimately reducing cycle time by up to 3.5 seconds.

Each cavity of Foboha’s 48-cavity mold has been equipped with a Priamus sensor to offer complete system monitoring and optimized use of the Priamus process control system. The 48-molded parts will be removed by a robot equipped with grippers from Gimatic, Molding Solutions’ affiliated business within Barnes. This mold will run at Fanuc’s booth. In addition, Cube Inclusive Turning Inserts (CITI), a technology patented by Foboha, is highlighted for its suitability in producing multi-component parts, where the second material is desired on both sides of the basic body.

Related Content

Hot Runner Mold, Cable Checker Troubleshoots Mold System Failure

PCS Company’s MoldXChecker and CableXChecker offerings detect open and shorted circuits and troubleshoots faulty temperature control cables respectively.

Read MoreVIDEO: Can You Integrate a Joystick onto a Robot for Mold Repair?

Tony Demakis, President of Alliance Specialties and Laser Sales and Brian Conner, Channel Development Manager at Universal Robots answer the question of whether or not you can integrate a joystick onto a robot for mold repair.

Read MoreHot Runner Systems, Controllers, Auxiliary Injection Unit Exhibitions

Mold-Masters exhibits a wide variety of new and enhanced systems and technologies at K Show like the TempMaster manifold plastic leak detection, the PET-Series two-stage hot runner system and Fusion Series G3.

Read MoreAI Augments Injection Molding Process Control System

MAX, a new process advising feature added to RJG’s Copilot system, is engineered to help troubleshoot and optimize the injection molding process and addresses industry skill gap.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More.jpg;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)