Mantle to Deliver Production Metal 3D Printers for Moldmakers, Molders

Demonstration of continued market momentum is seen by delivery of the P-200 printer to Westec Plastics and Westminster Tool’s success with a Mantle beta system. Mantle will be featuring these achievements at this week’s MoldMaking Conference.

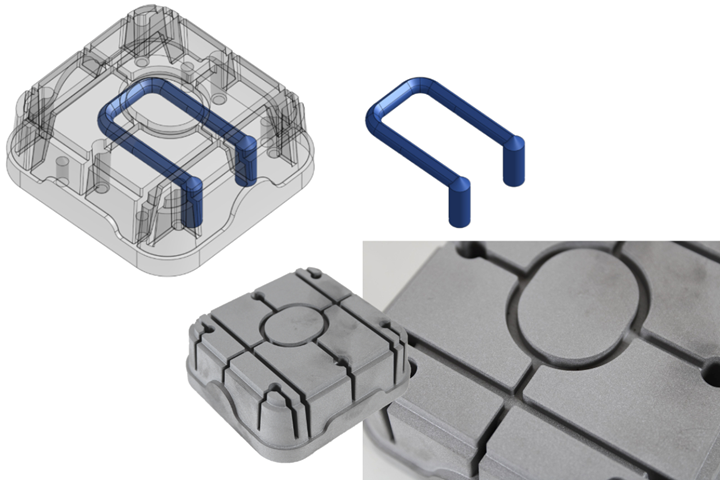

Westminster’s H13 insert developed for Xpress7 is shown above, including its metal 3D printed conformal cooling (top left), the completed 3D printed mold insert (center) and a closeup of the insert’s deep ribs. Photo Credit, all images: Mantle Inc.

Mantle Inc. has announced the deployment and continued market traction for its metal 3D printing system that automates how OEMs, molders and moldmakers make precision mold components, reducing lead times and costs while accelerating how manufacturers go from product idea to launch.

After completing multiple successful beta deployments, the company is shipping production versions of its P-200 printer and F-200 furnace incorporating additional hardware and process refinements. Westec Plastics, a custom plastic injection molder and tool builder based in Livermore, California, received the first Mantle production system.

“Having the Mantle equipment in-house enables Westec to complete prototype and production steel tooling inserts with a much shorter lead time than standard mold builds,” Tammy Barras, president of Westec Plastics, says. “This will benefit our customers by providing production-quality steel tooling with aluminum tooling lead times.” (Read “Westec Plastics 3D Prints Mold Inserts Using TrueShape Technology” for more information.)

Another Mantle customer, Westminster Tool, has successfully ued its Mantle beta system for more than 1 year. This manufacturer of precision molds located in Plainfield, Connecticut, has produced components for prototype and production tools, including this announcement of a complex mold insert for an industrial customer that was ordered by Xpress7, a Minnesota-based mold builder. Westminster Tool applied Mantle’s high-precision shaping capabilities to print the insert, significantly reducing the cost and lead time by eliminating more than 180 hours of EDM work and all CAM programming (full case study here).

“The advantages of Mantle’s technology are multiplied when it replaces traditional EDM operations. Running almost entirely unattended, it allows us to accomplish similar geometries with a fraction of the personnel and skill level,” Hillary Thomas, Westminster Tool vice president, says.

Mantle will be featured in a joint presentation at the Molding and MoldMaking Conferences on Aug. 29-30, 2023 in Minneapolis, Minnesota. The panel presentation entitled “Metal 3D Printing that Makes Dollars and Sense” will feature Mantle, Westminster Tool and Nicolet Plastics, which is also deploying a Mantle metal 3D printing system.

Related Content

-

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.