Imagine finally deciding to invest in conformal cooling, then having that investment clog up and everyone saying, “I told you so”. The two biggest objections to implementing conformal cooling are channels plugging up or shops believing that they do not have ‘perfect water’ in their plant to use this approach successfully. The reality is that all cooling lines plug up or build up scale, if the toolroom does not properly maintain the inserts. Plus, no shop has perfect water.

Let’s explore a three-step maintenance strategy commonly used for additive tooling that incorporates conformal cooling.

-

Control Water Quality and Filtration

The first step to success with conformal cooling preventative maintenance is to use localized filtration and to seek expert advice. Water quality is a never-ending challenge when it comes to finding the right balance within your system and there are many solutions to controlling water chemistry. So, if you do not have a subject matter expert in your plant seek out a local service that will help you check the chemistry and provide the right solution.

Whether you are running off a central process cooling system or a local thermolator at the press, place a local filter as close to the mold as possible. The most effective method used by many molders is a 5-micron inline filter unit with a flowmeter on the outlet to monitor the flow rate. The 5-micro filter is very effective as they offer a 7-15 GPM flow, which is sufficient for typical conformal cooling circuits.

Placing a flow meter at the outlet enables you to monitor the filter before the flow drops below the cooling circuit’s requirements and it starts to reach its end of life. The goal is to optimize filter life before replacement. Adding this step to the cycle checklist, so the team can monitor the filter during production at the expected intervals will prevent clogging.

Placing one filter near each conformal cooling circuit enables a technician to monitor each circuit individually. Also, filtering individual circuits as close to the mold as possible removes major solids from the cooling source and prevents them from collecting in areas close to the heat source inside the mold insert where calcium builds up.

AM Tooling Maintenance

-

Boost Conformal Cooling

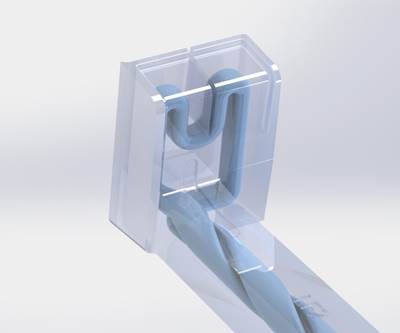

Conformal cooling channels in an additive mold inserts are the most restrictive area because the molding surface geometry that you must cool only permits small cooling lines. Plumbing these lines from the manifold or thermolator often starves the circuits because liquid tends to follow the path of least resistance.

For example, a manifold with all ⅜-inch NPT (ANSI/ASME B1.20.1 pipe threads) lines out to the mold and ⅛-inch NPT conformal cooling circuits cannot receive the necessary flow due to the increased pressure required to balance the flow. To provide enough pressure to maximize flow through those circuits, install a small inline pressure pump for those circuits off of the manifold. This approach permits added pressure onto the smaller circuits for optimal flow and avoids adding another thermolator for those specific circuits.

Controlling this flow with a flowmeter ensures that you are achieving the maximum flow rate and consistent production. These small pressure pumps are compact and easily available from industrial supply companies. Look for a pump that is a pressure pump rated for at least 10 GPM. Do not use a flow pump.

Also ensure the pump is rated for the high temperature ranges that your shop uses for process cooling.

The old saying “An ounce of prevention is worth a pound of cure” is very true when it comes to maintaining your investment in additive tooling.

-

Keep Your Cooling Circuits Clean

Once you eliminate major solids from the process cooling system and optimize the cooling flow through the conformal cooling circuits, it is time to create a maintenance plan that maintains the circuits cleanly and completely during each mold preventative maintenance.

Here is a look at three highly effective ways to clean your cooling circuits to help you determine which method best suits your toolroom’s preventative maintenance program.

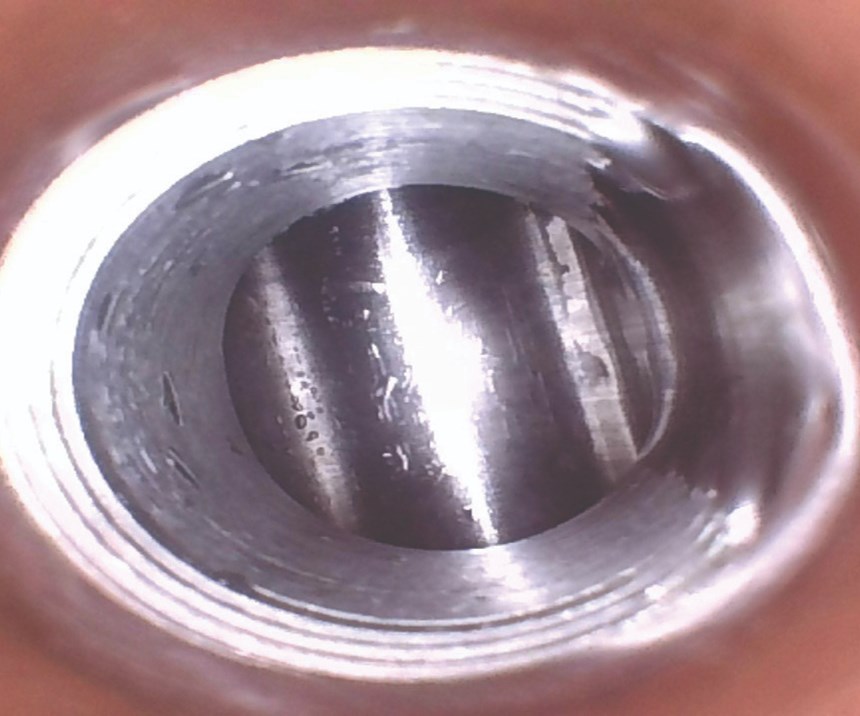

1. Ultrasonic cleaning. This method requires a technician to disassemble the mold and submerge the inserts in a ultrasonic cleaning unit comprising a series of tanks that use high-frequency vibration to scrub the part surfaces. It is critical to ensure that the entire cooling circuit is full of liquid, so the ultrasonics cavitation power can do the work to clean off any scale buildup in the wall of the circuits.

Perform this step in when you clean any plastic-touching inserts during your standard mold preventative maintenance process. Ultrasonics thoroughly cleans out the plate and removes gas residue in the vents to keep the mold breathing efficiently. This cleaning method is a must for any shop performing mold maintenance.

2. Flush descaling. A toolroom can run this system between production runs with the mold assembled. The unit acts similar to a thermolator with the cooling circuits hooked up to it. The unit can cycle in the press or on the bench for 1 to 4 hours depending on the scale buildup.

Knowing the flow of each circuit at mold validation serves as a baseline. Descaling units are equipped with a flowmeter to monitor the flow as it cleans. It then identifies the moment the flow matches the original flow rate, so the users knows that the lines are clean and free of scale.

These units also add a layer of protective coating to avoid future scale buildup until the next cleaning. Several unit types are on the market, so do your research and ask for a demonstration to confirm that the unit is an appropriate option for your mold.

3 Coatings. Beyond these two preventative actions, advanced coatings are another solution for maintaining optimal efficiency in any conformal cooled additive tooling. For example, ceramic coatings repel scale buildup in the cooling lines that lead to restrictions.

Technicians apply ceramic coatings through a special process that helps it conform uniformly to the substrate, eliminating buildup in corners and flaking, chipping or peeling and preventing corrosion and buildup in the cooling circuits. If your shop is looking for additional protection, coating the circuits provides that extra peace of mind for environments where process cooling is not very stable.

The old saying “An ounce of prevention is worth a pound of cure” is very true when it comes to maintaining your investment in additive tooling. Implementing these simple steps into your process through standardized preventative maintenance will eliminate tooling issues with plugged-up circuits and enable your shop to run production at the quoted cycles, while avoiding defects for the life of the program. These simple strategies can make a big impact on the savings your conformal cooling investment can bring.

Next Chapter Manufacturing

Related Content

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreExploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

Read MorePlastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

Selling the Value of Additive Tooling in a Mold

Gaining molder buy-in for a conformal-cooled mold insert requires communicating the mold’s total cost of ownership over the life of the project.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More.jpg;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

_970x250 3.png;maxWidth=970;quality=90)