November Product Highlights

In this most recent roundup, MMT continues to present the breadth of new or proven technologies that target the moldmaking industry, from cutting tools to software to molding-related products, that have been shared this month.

Too busy during the holidays to keep track of MoldMaking Technology’s daily product posts? We’ve got you covered.

This is MMT’s November digital-only product/service roundup to keep you informed and your shop engaged in the latest and greatest products that are being offered in the moldmaking industry whether it’s to aid in milling and drilling operations, troubleshoot water leakage in your mold or eradicate dead spots behind your valve pins.

MMT publishs new/proven products/services on a daily basis, so browse our “New Tech” section on the homepage of our website, or find them via the website search bar. Follow each title link below for the full product post.

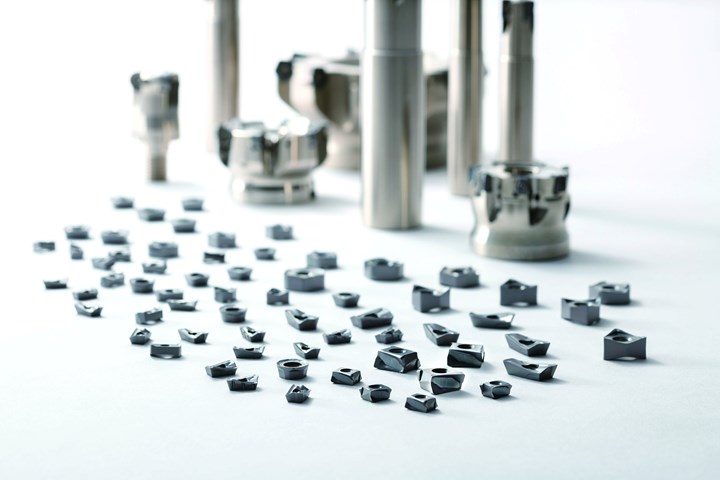

Indexable Inserts, Toolholders Perform Heavy-Duty, Wide Profile Grooving

Heavy-duty grooving and wide-profile grooving is achieved through Tungaloy NTK’s TungHeavyGroove grooving inserts and toolholders. An enhanced insert clamping design provides optimal tool rigidity. TungHeavyGroove’s operations may be implemented for venting grooving in injection molds, the company notes, though it depends on the geometry of the venting that is needed — in particular, venting channels for round components is possible using TungHeavyGroove.

Shrink-Fit Machine Features Integrated Cooling

Photo Credit: Haimer USA

Haimer USA displays its Power Clamp Air i4.0 Eco, a high performance shrink-fit machine with integrated cooling for all cutting tools (solid carbide and HSS). According to Haimer, the machine is suitable for reliable shrinking and cooling of shrink-fit collets and toolholders. It provides smooth and clean cooling of all kinds of toolholders or collets by air, without dirt and water residue.

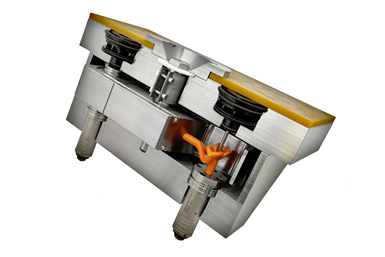

3D-Printed Manifold Engineered to Eradicate Dead Spots Behind Valve Pins

Hasco Hot Runner is presenting the new manifold concept Streamrunner Shadowfree, an advanced 3D-printed hot runner system engineered to eradicate “shadow formations” behind valve pins.

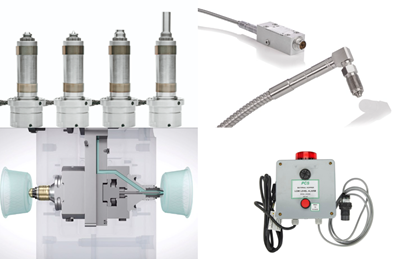

Temperature Control Unit Enables Cycle Time Cuts

Photo Credit: Frigel North America Inc.

The Microgel Syncro from Frigel North America is a new press-side unit that the machine builders say revolutionizes the temperature control method for injection molding.

Frigel says Microgel Syncro technology enables a drastic reduction in cycle time (up to 40%), while maintaining the surface quality, dimensional characteristics and mechanical performance of the finished product. The cut in total cycle time is accomplished thanks to the reduction of the cooling time only.

Cutting Tool Presetter Offers Advanced Productivity in a Smaller Footprint

Lyndex-Nikken, manufacturer and provider of high-performance machine tool accessories, announces the E346V+ presetter, by Elbo Controlli Nikken, delivering the productivity of larger, more sophisticated presetters in a smaller footprint.

Read Next

Moldmaking-Related Technology Highlights

This month’s tech roundup highlights mold materials and other miscellaneous technologies for moldmaking needs.

Read MoreProduct Innovations Pushing the Mold

Another tech roundup is here to provide an overview of technologies and services on the market for moldmakers. Featured in this roundup are cutting tools, mold components and more.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)