Centers of Excellence for Moldmaking

As seen in our February article on using supplier collaboration to improve profitability, this same blow moldmaker knows the value of strategic partnerships. For example, they recently teamed up to create Centers of Excellence for the design and manufacture of injection blow, injection stretch blow and extrusion blow molds.

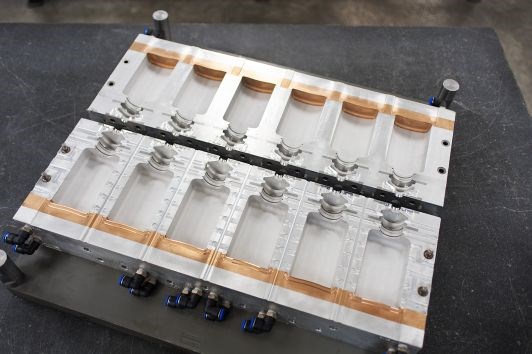

As seen in our February article on using supplier collaboration to improve profitability, this same blow moldmaker knows the value of strategic partnerships. Creative Blow Mold Tooling of Lee’s Summit and Big 3 Precision located in Centralia, Illnois recently teamed up to create Centers of Excellence (CoE) for the design and manufacture of injection blow, injection stretch blow (IBM/ISBM) and extrusion blow molds (EBM). These CoE are built upon Creative's 30 years of experience in EBM tooling and Big 3's focus on the IBM/ISBM market.

The goal of the partnership and the CoE is to help existing customers with speed to market through increased product development and support. Big 3 and Creative also intend to use the CoE concept to help balance engineering and manufacturing capacity, increase efficiencies, and further reduce lead times for customers. The partnership will allow customers to source tooling on complementary platforms through a known and trusted business partner.

As a primary supplier, each company will be able to tap into the CoE for engineering and manufacturing leadership, project management, and technical support. The primary supplier will be responsible for program management and manufacturing. The newly formed alliance will be a partnership of the companies’ technical capabilities and expertise.

Related Content

-

2021 30 Under 30 Honors Program: Mentoring in the Next-Generation of Moldmaking Professionals

Young professionals are vital to the moldmaking industry, and it is important to acknowledge those making strides in shaping the industry's future. MoldMaking Technology recognizes the industry's young talent through its 30 Under 30 Honors Program.

-

Exploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

.png;maxWidth=300;quality=90)