Hot Runner Systems

A hot runner system is an assembly of heated components used in plastic injection molds that inject molten plastic directly into the cavities of the mold. Unlike cold runner systems, hot runner systems do not require sprue and runner systems. They are feed systems that convey molten plastic from the machine nozzle into the cavity. It uses a heated manifold to keep that plastic in a molten state. The heated plastic travels from the molding machine nozzle through internal channels called “hot runners” and can be delivered into multiple cavities at the same time. The only component that needs to be removed each cycle is the part itself, ensuring the mold can be cycled again very quickly. The increased cycle time and reduced plastic waste is ideal for high-volume production.

Hot runners can inject plastic directly into the part cavity, which is how they differ from cold runner systems. They are also larger and more complex than cold runners which results in longer setup times and increased installation costs.

Hot runner systems consist of the following components:

- Nozzle body (also known as the drop)

- The link to the cavity. They are either directly gated into the part, or into the sub runner, which will lead into the cavity. Valve gate pin is dropped through this part

- There four style categories available:

- Threaded nozzles

- Support ring nozzles

- Single valve gate nozzles

- Sprue Bushings

- Manifolds

- Flow control

- Controls the melt flow in the form of valve gate nozzles or even control systems

- Connections

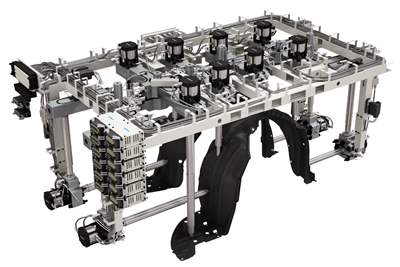

- Hot halves

ESSENTIAL READING

VIEW ALLHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreHow to Build a Better-Performing Hot Runner Mold

Early stage communication across the supply chain about design considerations optimizes hot runner mold performance.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreHow to Transition From a Cold to Hot Runner Mold

Reducing cycle time and costs while also freeing up your machines for other projects are advantages gained by using hot runners that no one can ignore. But where does one begin transitioning from cold to hot runners?

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreLatest Hot Runners News And Updates

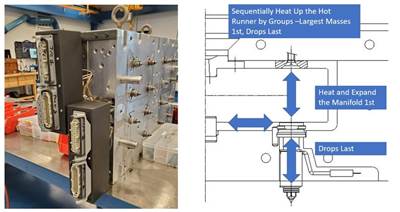

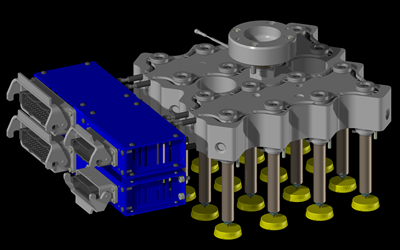

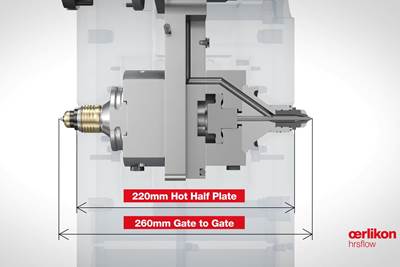

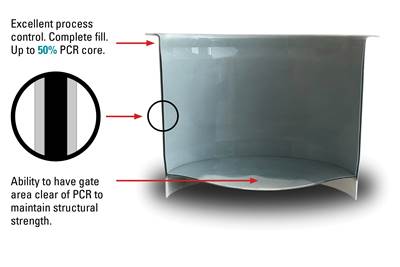

Stack Mold System Combines Fast Injection With High Process Repeatability

NPE2024: Primarily designed for thin-wall packaging applications, the patent-pending mold design by Oerlikon HRSflow brings consistency, simplified maintenance and assembly and a sustainable materials focus.

Read MoreLSR Platform Meets Critical Medical Molding Needs

NPE2024: Recent updates to Mastip’s Aquilo platform highlight how its design — from consistent thermal profile to uniform cooling — has made it successful for medical industry projects.

Read MoreMoldmaking, Plastics Innovations Designed to Boost Injection Molding, Streamline Operations

NPE2024: PCS Company introduces several new products, including the MCS system, hot runner alarm systems, sprue bushings, a micro-TIG welder and its full Smartflow product line.

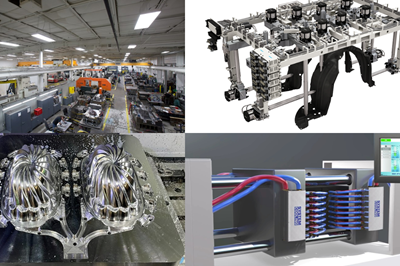

Read MoreHot Runners, Auxiliary Injection Units Enhance Control, Processing Capabilities

NPE2024: New hot runner systems, temperature and motion controllers, an auxiliary injection unit, a gate seal and sustainable processing solutions will be displayed at Mold-Master’s booth.

Read MoreHow to Maintain Heaters, Thermocouples, Valve Gates and Controls

An examination of real-world problems and solutions involving hot runner system maintenance.

Read MoreHot Runner Processes Commodity Resins for Cost-Sensitive Applications

Mold-Masters’ EcoONE series hot runner system is optimized for consumer goods, small home appliances, basic automotive components and other applications.

Read MoreFeatured Posts

Hot Runner Truths, Myths and Overlooked Areas

Addressing hot runner benefits, improvements and everyday issues from the perspective of decades of experience with probably every brand on the market.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreVIDEO: Why Is Sustainability Important to Mold Builders

Marta Orozco with DME shares ways mold builders can be a part of building a more sustainable future.

WatchCAM Automation, Hot Runners, Asset Management & More: The Best of August

What does CAM automation, hot runners, and simulation software all have in common? They are all topics that made it into our top ten most-viewed content pieces in August.

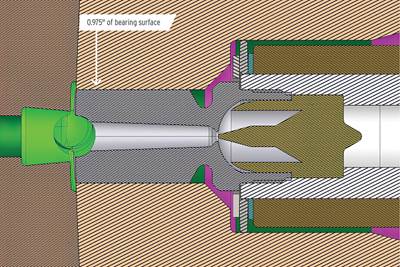

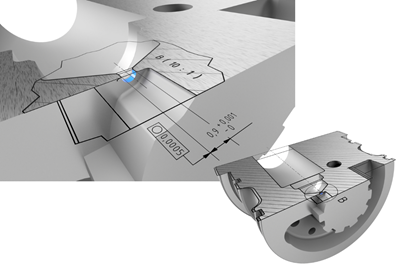

Read MoreHow to Cut Setup Time, Extend Gate Life With the Right Machining Strategy

Microcut honing provides high-precision machining of needle valve nozzles and guides in hot runner systems.

Read MoreHow to Build a Better-Performing Hot Runner Mold

Early stage communication across the supply chain about design considerations optimizes hot runner mold performance.

Read MoreFAQ: Hot Runners

What are the different types of hot runner systems?

- Hot tip: Standard, general-purpose version. Considered to be more economical than valve gates and is ideal for mass production of simple parts and products

- Valve gate: Features a mechanical valve that automatically closes when the machine injects plastic into the mold, resulting in a smooth enclosure and no visible surface abrasions on the product. Ideal for highly aesthetic projects. More efficient, but more expensive as a result

What are hot runner systems typically used for?

- Cell phone cases

- Bottle caps

- Projects that require a high volume of inexpensive parts

- Other high-volume items

What are the advantages of hot runner systems?

- Elimination of the runner: helps with cost, etc.

- Cycle time reduction/lower processing cost

- Improved molding system efficiency: No need to remove solidified plastic, etc.

- Optimal part quality

- Molding automation: can continue running

- Design flexibility

- Balanced melt flow: Melt channels are in separate, heated manifolds (same distance being filled)

What should moldmakers consider when purchasing a hot runner system?

Evaluating the cost justification for a hot runner mold requires careful consideration of cycle time, material type, annual volume, available press size and power consumption, as well as the cost of utilities, resin pricing, allowable regrind percentage and labor rates. Here are three key areas to consider:

1. Cold Vs. Hot Process Considerations

Cycle time is the primary cost measure of the molding process, and cooling represents about 80% of the molding cycle. The thicker the part, the longer the cycle time. However, the runner could determine the cooling time, and increase cycle time more than expected if the runner is thicker than the part.

The minute the resin leaves the machine barrel, the material starts to cool and solidify. This, in turn, causes injection pressures to climb and can yield unfilled parts, stress and warp. Limit the l/t ratio (length of flow versus part thickness) to avoid this outcome. Generally, a ratio under 100 is considered general-purpose molding and does not require increased injection pressures.

In a cold runner mold, the l/t ratio is measured from the start of the cold sprue, where the material leaves the heat source and begins to cool, which continues through the entire runner to the furthest point in the part (last point of fill). For example, 1 mm (0.039 inch) thick resin can flow easily 100 mm (3.94 inch). However, if a hot runner is used, the l/t ratio starts at the gate, reducing flow length and the injection pressure required to fill the part.

The higher the ratio, the more injection pressure is required to fill the part. A cold runner is included in the l/t calculation when the molder measures at the point of no added heat. This is one reason hot runners are appealing and can make the difference between molding a good or bad part.

2. Material Considerations

Most polyolefin resins can be reused without issue. Engineered materials can be limited in regrind content because each time the resin is processed, it experiences another heat history that can degrade melt quality and impact performance, color, rigidity, tensile strength, etc.

Keep in mind, not every runner makes it to the granulator, and not every pellet makes it back to the hopper. While eliminating the cold runner can reduce scrap, a complete hot runner system might not be cost-justified based on low annual volume. The cost of an entire hot runner system may take longer than a year for payback. It might be wise to consider a hot/cold combination or at least a heated sprue bushing. The sprue is typically the thicker portion of the runner, and eliminating that and/or a portion of the runner could have an impact on the cycle time, resin consumption, scrap, etc.

In some applications, a hot runner system might eliminate scrap from unusable runners, but based on the required shot size volume (total volume of parts and runners) relative to the barrel volume, and it might reduce the consumption causing the barrel of the molding machine to be too large. Residence time on engineered materials would increase, which may cause other issues. For example, too small a shot can be challenging to process even with olefins.

3. Energy Considerations

Hot runner systems run on electricity like granulators. An injection molding machine takes roughly 1 kiloWatt (kW) to process 1 kg (454 lbs) of resin. Reducing the shot size to parts only can have a significant impact on power consumption. It stands to reason that only heating, melting and processing parts takes less energy than parts and runners.

When deciding between a cold or hot runner system, consider all of these variables, which combined can increase productivity and energy savings, improve material utilization and reduce floor space and noise requirements on the shop floor.

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)