Components of a Mold

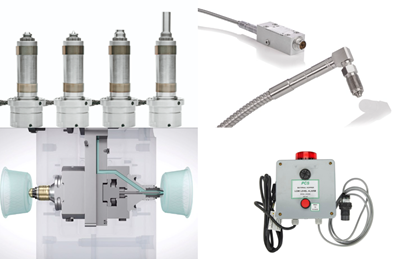

Mold components are what make the mold work and the mechanisms used to deliver a quality end product. Key components include mold bases, pins, ejectors, lifters, bushings, guides and alignment devices.

Mold components can be broken down into three categories: frame plates, frame components, and cavity tooling.

Frame or base plates consist of the individual mold plates which can be seven plates in a stripper plate mold or even up to twenty plates or more, depending on the size and complexity. Frame components include all tooling that is within the frame that does not form the part. This includes guide or leader pins, bushings, return pins, interlocks, bolts, and seals. Tooling that may also be included in this category is ejector pins. Cavity tooling is the most critical and expensive tooling of a mold because it determines dimensional and aesthetic part features. It includes the cavities, cores, sleeves, and pins that directly form the part.

ESSENTIAL READING

VIEW ALLA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

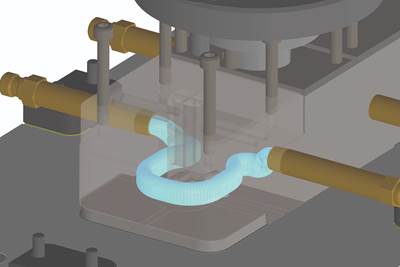

Read MoreHow to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreVIDEO: How to Change Out Molds in 10 Minutes or Less

Is a 10-minute mold change possible? Check out this demo to see how it can be done.

WatchHow to Solve Core Pull Flash and Part Issues

Many mold problems can be solved by simply providing enough preload force on the core to prevent movement.

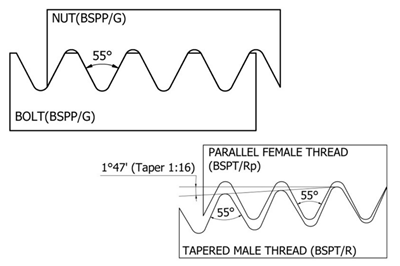

Read MoreHow to Machine and Seal Metric Cooling Line Threads

Understanding the machining of British standard pipe parallel (BSPP) and British standard pipe taper (BSPT) straight threads helps identify why a cooling plug may not be sealing correctly.

Read MoreLatest Mold Components News And Updates

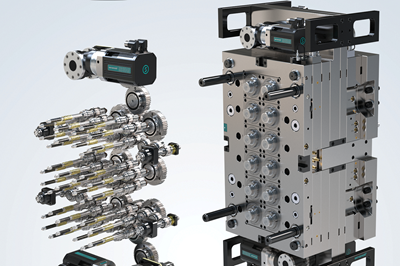

Servo Unscrewing Device Delivers High Performance to Multi-Cavity Molds

NPE2024: Electric Servomold systems by DME answer the demands made on high-performance injection molds, enabling precise, more environmentally friendly process reliability.

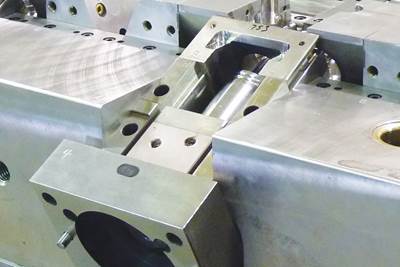

Read MoreHydraulic Locking Cylinders Offer Faster Mold Builds With Zero Flash Performance

Off-the-shelf Kor-Lok “mini” model 70 and other side action systems by PFA come in more stocking options and next-day delivery to accelerate mold production.

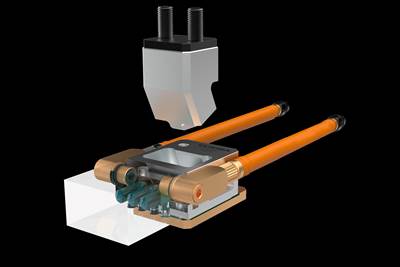

Read MoreCompact Slides Provide Option for Difficult-to-Cool Locations in Molds

CUMSA introduces a new cooling system feature to its compact slides lineup to remove heat during the molding process.

Read MoreEjector Pin Selection Guide

A review of materials, treatments and coatings to help determine the proper pins for optimized plastic part ejection.

Read MoreBonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

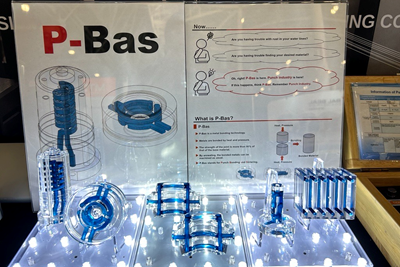

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

Read MoreGuide Element Program is Expanded

Guide elements with a snug-fit feature are now available to Hasco customers in an effort to reduce damage to tool inserts and cores.

Read MoreFeatured Posts

VIDEO: Why Is Sustainability Important to Mold Builders

Marta Orozco with DME shares ways mold builders can be a part of building a more sustainable future.

WatchProduct Innovations Pushing the Mold

Another tech roundup is here to provide an overview of technologies and services on the market for moldmakers. Featured in this roundup are cutting tools, mold components and more.

Read MoreTechnology and Sourcing Guide 2023: Mold Components

Mold components make the mold work and the mechanisms used to deliver a quality end product. Key components include mold bases, pins, ejectors, lifters, bushings, guides and alignment devices.

Read MoreAn "Impossible" Automation Project Still Proves Invaluable

Two years later and a once-thought-impossible automation solution is still proving its worth to this high-mix, low-volume manufacturer via variable capacity.

WatchTo the Next Level: Hot Runners, Mold Components Solutions and Services

Moldmaking can be a complex business, but things can be simplified with the right hot runner and mold component technologies and services.

WatchVIDEO: Taking a People Before Product Approach to Growing a Business

Angela Elsey, President of PCS Company, shares her journey into moldmaking, perspective on the industry and plans for the business.

WatchFAQ: Mold Components

Should I use standardized mold components?

There are many benefits to working with standard components. For starters, the leadtime on a project can be reduced. The time that would have been spent squaring up blocks, machining, heat treating and grinding all of the slide components can be used to focus on the molding area—cores, cavities, slide faces, etc. Programming time for the slide components is eliminated, and once the mold designer is tuned in to the idea of using standard slides, design time should also be reduced.

What about cost? It is debatable. Depending on how long you determine it takes to manufacture all of the components of a slide assembly and what you use for a shop rate, the price of standard slides could be considered a bargain or overpriced. You will need an accurate assessment of the time it takes to design and build a slide assembly.

How can I fix core pull flash and part problems?

Many problems can be solved by simply providing enough preload force on the core to prevent movement. Nonetheless, blocks and pins only provide a backstop to a core and often provide little to no active support to prevent movement. These methods rely on steel’s mass or volume to minimize flex and movement to yield a “good enough” result. In this way, there is always some reaction to the forces of injection from the perfect positional geometry, rather than a proactive preloading of metal into position.

How do self lubricating mold components work?

Using self-lubricating mold components has significant benefits, but only if the molder truly understands what these components are: essentially a conventional component with lubricant added in the form of graphite plugs. Graphite is a solid lubricant, so, for those molders who are used to working with liquid lubricants such as grease or oil, a solid lubricant may seem a little strange, and so might the graphite itself.

Graphite has a near-zero coefficient of thermal expansion, which means that it doesn’t expand and contract with temperature changes like ordinary substances do. It’s not a metal, but it conducts electricity like one. It also doesn’t melt. Instead, it remains a solid at temperatures ranging to 10,000°F and then becomes a gas. It’s not very strong, but it can be formed into composites with incredible strength.

Features and Functions

The main function of a self-lubricating mold component is to guide and control movement. Such a mold is typically made of aluminum bronze, an excellent bearing material, with embedded graphite plugs. The mating part of the mold (the one being guided) is usually made of hardened steel. As the two parts move relative to each other, the very slippery one-atom-thick sheets of graphite peel off and become distributed over the wear surface. With each cycle, a bit more graphite is distributed, so the process continuously replenishes. Graphite doesn’t evaporate and is relatively inert, so the lubrication it imparts is essentially permanent.

Although self-lubrication adds about 20 percent to the cost of a conventional component (one that must periodically be greased), there are several benefits for this extra cost:

• Maintainability. The need for periodic greasing is eliminated, which means, over the life of the tool, the savings in preventive maintenance (PM) is likely to be several times the upfront cost for self-lubrication.

• Reliability. Lubrication is always present, eliminating the risk of failure or shortened life due to skipped PM. Also, the absence of liquid lubricants means there is nothing to attract grit and other contaminants to wear surfaces.

• Simpler designs. With self-lubricated components, there is no need to make provisions for periodic lubrication, which removes a design constraint, potentially reducing costs and/or improving functionality.

• Clean operation. No liquid lubricants to drip or spatter on parts means a very clean operation with less scrap and rework.

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)