Additive Manufacturing

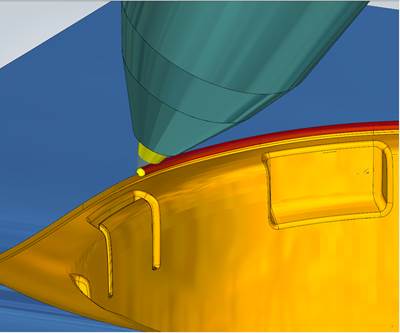

How to Select the Right Programming CAM Software for Directed Energy Deposition in Mold Repair and Modification

Selecting the right programming CAM software improves the use of directed energy deposition to repair and modify tooling.

Read MoreOpen Software Technology Refines 3D Printing and Scanning Workflows

Siemen’s Parasolid geometric modeling software now offers tools for Convergent Modeling and lattice structures.

Read MoreComparing 3D-Printed Conformal-Cooled Steel Molds to Aluminum Molds

While 3D-printed conformal coolant lines in steel injection molds reduce production costs and improve part quality, aluminum molds can yield similar results faster and at a lower cost.

Read MoreAdditive Manufacturing User Group awards ten DINOs

Every year, AMUG’s DINO awards recognize those that have contributed to the AM industry with the intent to advance other individuals or the industry as a whole.

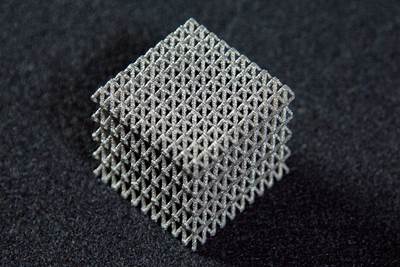

Read MorePrint the Whole Injection Mold in HSS to Increase Tool Life

A German mold builder offers a solution for printing high-speed steels with high carbon content to produce highly dense and wear-resistant molds via selective laser melting.

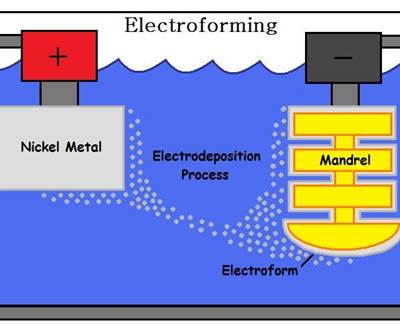

Read MoreA Multi-Metal Additive Approach to Optical Quality Molds

Researchers propose a new approach to producing mold inserts with optical surface quality and no degradation using electroforming, thermal spray, and selective laser melting.

Read More2020 Sourcing & Technology Guide: Additive Manufacturing

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services with 11 sections, including Additive Manufacturing.

Read MoreAdapting to New Ways of Working During COVID-19

Mold material suppliers are in the fight against COVID-19 just like their mold-building customers, and learning similar lessons too such as the benefits of going paperless and working remotely.

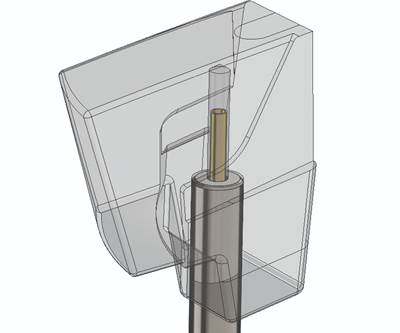

Read MoreHow to Use Additive Tooling in Difficult-to-Cool Areas of a Mold

Difficult-to-cool areas of a mold cost cycle time, making the perfect application for additive tooling, including retrofitting an existing tool with lifters, slides and high wear areas.

Read MoreHybrid Milling Machine Effectively Vents Gas

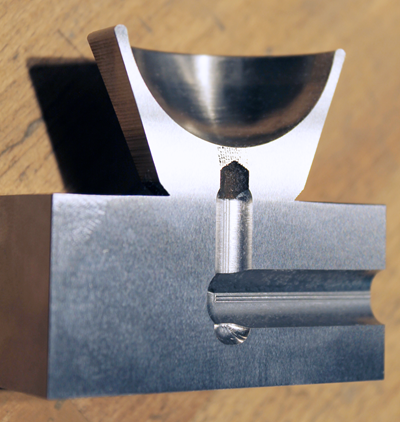

Matsuura Machinery USA Inc.’s Lumex technology makes effective mold/gas venting possible and improves the quality of molds.

Read More

.JPG;maxWidth=400;quality=70)

.jpg;maxWidth=300;quality=90)