Open Software Technology Refines 3D Printing and Scanning Workflows

Siemen’s Parasolid geometric modeling software now offers tools for Convergent Modeling and lattice structures.

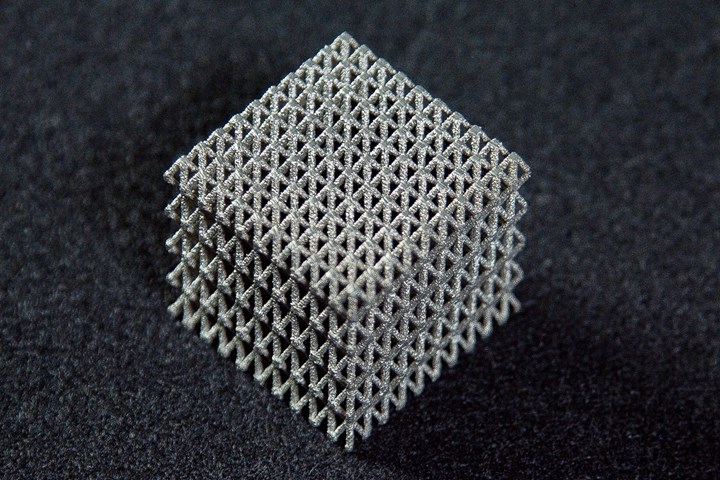

Photo Credit: Siemens Digital Industries Software

The release of Siemens Digital Industries Software’s Parasolid open software technology for geometric modeling is said to enable the solving of the most difficult technical challenges and improves upon 3D printing and scanning-based workflow with new tools for Convergent Modeling and lattice structures.

According to Siemens, the advances in Convergent Modeling provide engineers greater efficiency in workflows that need to mix facet and B-rep geometry. Further, the support of lattice structures—repeating networks of nodes and beams that offers increased strength-to-weight ratio while maintaining the required structural integrity—enables engineers to design parts with reduced material requirements and mass. Further, the functionality gives 3D printing a new level of accessibility and improved performance benefits.

Related Content

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking enabled the speed necessary to iterate to a solution.

-

3D Printing Accelerates R&D Process For Prototyping Molds

Utilizing Axtra3D’s additive technology, LSI Solutions, a medical equipment manufacturer found the compatible machine it needed to accelerate its R&D process for prototyping molds for medical devices.