Automation Technologies and Strategies

Integrating automation technologies and strategies is key for improving overall mold manufacturing operations. Challenges and solutions for achieving a level of lights-out machining/ unattended operations are met via the use of a variety of automation options including, robots, work cells, tool management and software.

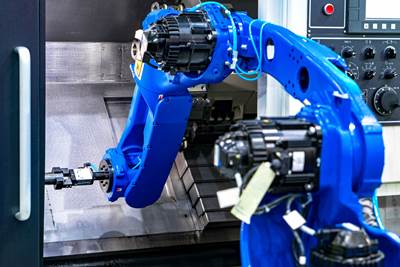

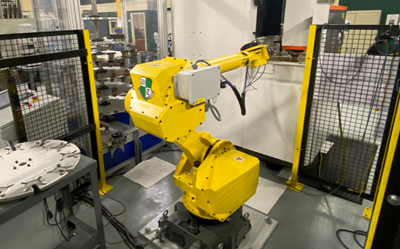

Machine-tending robots are often key components used to enable unattended or lights-out machining operations, adding capacity by taking advantage of time that’s currently unused, like nights and weekends. In many cases, robot integration enables shopfloor employees that were previously loading and unloading parts from machines to perform duties of greater value. Plus, today’s robots are faster and more intelligent than in years past and are also becoming increasingly viable for small-batch/high-mix production. In addition, collaborative robots, or “cobots,” use sensor technology that enables them function safely alongside humans in a shared work environment. That means no more isolating fencing is needed to separate worker and robot.

ESSENTIAL READING

VIEW ALLHow to Build the Right Automation System

Seven considerations when developing an automation solution for your customers.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreHow to Machine Micron-Level Precision Molds in One Try

On-machine measurement intelligence and modification technology helps mold builders overcome machining variables and quickly produce micron-level tolerances.

Read MoreHow to Use Automation to Minimize Mistakes and Speed Mold Build Process

A guide to capturing and reusing company knowledge and experience with software automation.

Read MoreHow to Start Automating Your Moldmaking Operation

A few fundamentals of moldmaking automation include identifying key areas and places to avoid and addressing common concerns and roadblocks.

Read MoreThree Advances in Vision Measuring Technology for Moldmaking

Next-generation metrology solutions are streamlining shopfloor automation and quality control for mold builders.

Read MoreLatest Automation News And Updates

How to Build the Right Automation System

Seven considerations when developing an automation solution for your customers.

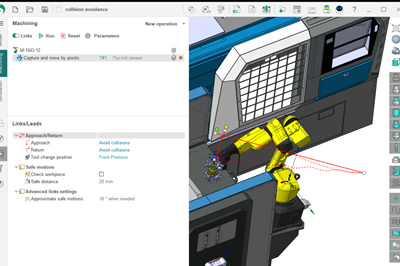

Read MoreRobotic Programming Suite Introduces Enhanced Functionalities, Improvements

SprutCAM X, an all-in-one CAD/CAM/OLP software suite for complex and creative robot tasks, has updated its Collision Avoidance feature, amongst others for a more streamlined experience.

Read More3 Technologies to Help Fill the Skills Gap

Moldmakers can address the labor challenge with robotic systems, simulation products and metal 3D printers.

Read MoreMMT Chat: Key Principles of an Automated System

PFAFF Molds develops its automated systems to address key customer pain points – such as high worker turnover, rising costs, volume fluctuation and sustainability.

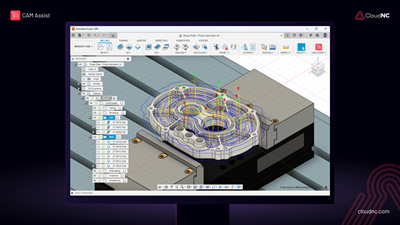

WatchAI-Aided Software Accelerates CAM Programming Time by 80%

CAM Assist from CloudNC automatically generates professional machining strategies in seconds, enabling U.S. manufacturers to be more productive, reducing lead times and eliminating the skills gap.

Read MoreDiscover Metalworking Technologies Targeted to Mold Shops

What EDM, automation and machining technologies are currently available to the mold manufacturing industry? MMT has compiled a list of some of the latest.

Read MoreFeatured Posts

How to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreWhat Does Automation Look Like in Moldmaking?

There are a variety of technologies and products that can help optimize and automate the manufacturing processes involved in moldmaking.

Read MoreMoldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

WatchCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreMold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

Read MoreAn "Impossible" Automation Project Still Proves Invaluable

Two years later and a once-thought-impossible automation solution is still proving its worth to this high-mix, low-volume manufacturer via variable capacity.

WatchFAQ: Automation

What is automation?

“Robot” is the first picture that comes to mind, but it means more than that. Automation could be machines that are able to do more in one setup, one handling. It also refers to other options like pallet systems for moving work around, in and out of machines. It refers to software that can automate certain operations. Automation is not a replacement or an alternative for people.

What is a cobot?

A collaborative robot or “cobot” is a robot that is safe to run unguarded near people. Most cobots are safe because they are speed- and force-limited, and they stop upon sensing contact with an obstacle. Cobots are also easy to relocate and reprogram for different tasks in a shop.

What should you know about cobots?

1. Cobots, vision and AI all go together.

2. Cobots do not guarantee safety.

3. Cobot applications need not feature collaboration.

4. Automation’s payback period is declining.

5. Trends in manufacturing favor collaboration.

6. Cobot adoption might be held back by lack of people.

7. Advancing AGV technologies make cobots mobile.

8. Attention recognition is coming.

9. Collaborative can be done in different ways.

10. “Collaborative” can be a bigger idea.

How do robots and 3D printing intersect?

1. 3D Printed End-of-Arm Tooling (EOAT)

2. 3D Printed Off-Robot Accessories

3. Robot-Tended 3D Printers

4. Robots As 3D Printing Systems

Why should moldmakers consider implementing automation into their shops?

Here are five big-picture considerations to shop automation:

- To reduce labor costs. Automation is already replacing human labor in areas such as picking and moving parts, assembly, inspection and more.

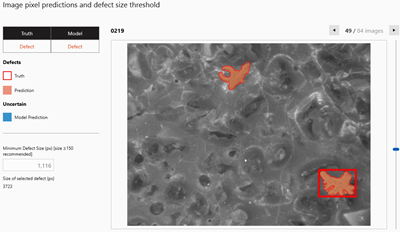

- To eliminate waste. In manufacturing, human error leads to wasted time and resources. Computers and machines can do many things faster and more accurately than humans – without making mistakes.

- For lightning-fast turnaround times. Automation lets you process orders faster, reduce setup and production times, and get your product out the door quicker.

- To improve quality and safety. Rework due to poor quality acts like an anchor on production time and lowers customer satisfaction. Workers’ comp costs can put large dents in your bottom line. Automating processes in these areas can raise quality ratings while making your workplace safer for employees.

- To future proof your business. Automation improves the ability to forecast trends, see how customer needs will change, and prepare for them from a technology and strategy standpoint so you can get there ahead of the competition. Automating the data-gathering process with dashboards provides immediate access to accurate, real-time data while reporting or displaying it in any format you choose.

(Source: 5 Reasons to Consider Automation)

How can automation help reduce the cost of mold machining?

The current method of processing five sides of a detail is very labor- and time-intensive and requires highly skilled mold builders. An alternative solution is a closed-loop tolerance control process that hard mills geometry for roughing and semi-finishing in hardened materials up to 95 HRA in carbide. Then, in the same setup, the machine verifies the tolerance using a probe in the spindle. Next, you grind the 2D geometries in the same machine and setup, including bores, bosses, pockets or free-form contours using chop, contour or face grinding. Verifying the grinding process follows. Finally, you use a spindle probe to confirm if the material is within a specified tolerance or rewind and apply cutter compensation.

This automated approach frees up your skilled workforce for other tasks. It also maximizes the utilization of your machining centers by finishing many geometries in one setup on one platform, although, it does not entirely replace your grinders.

(Source: How to Cut Mold Machining Costs in Half)

How can moldmakers design their molds to avoid automation problems?

There are eight specific areas of mold design during which the right decision can avoid problems for the robot or automation supplier and possibly save money on the purchase, installation or operation of the equipment. But compromise is always going to be necessary, so each of the following tips can be read with the assumption that they are preceded by the phrase, “If possible.”

1. Do not place inserts on the same side of the mold from where parts will be removed.

When the molded part requires inserts, it is always better to design the mold with the inserts positioned on one side of the mold and the parts retained on and removed from the other. This approach permits insert and part grippers on opposite sides of the robot’s vertical arm and avoids problems.

2. Avoid mold-locked parts.

Robots are not designed to physically pull a part off of a core or out of a cavity, as that movement places undesirable stress on the grippers and the arm. Avoid any mold lock or undercut, so when everything is working properly, the mold ejector system will start pushing the part out of the mold, and the robot only needs to grab the part and extract it from the mold.

3. Design the mold, so it shuts off on the inserts.

A robot is not designed to take an insert to a hard stop or to seat the insert in a position on the mold because these movements put unnecessary stress and wear on the robot. Instead, position inserts at a mold shutoff, so the mold closing pushes the insert into its final position. This is a simple way to ensure that the insert(s) cannot slip out of position due to machine vibration or material flow.

4. Watch what you put on top of the mold.

A molding machine that must wait an extra fraction of a second for a robot to get out of the way will increase costs over time. The key is to minimize the amount of gear on top of the mold, such as electrical boxes, water lines, or even slides or unscrewing actuators. If possible, mount this extra ‘stuff’ on the side of the mold, so it does not interfere with the robot as the mold closes.

5. Pay attention to gating.

All other things being equal, robot manufacturers will always prefer to automate a hot runner mold. The robot cycle is shorter (less time spent outside the mold) since there are no additional operations needed to separate parts from the runners, which is important for a fast-cycling part where the robot cycle time could be a limiting factor. The EOAT can be much simpler, too, since gripping and degating the runner will not require additional components.

Cold runner subgate or tunnel gate systems are the next most automation-friendly approach since degating is accomplished by the mold opening or by the ejection system. The robot only needs to pick the parts as they eject, and the runner simply falls out of the way, or more commonly, the robot picks both parts and runners and deposits them separately.

6. Locate left- and right-hand cavities.

Often parts must be molded in two opposite-handed configurations in the same mold. When two parts are molded in a four-cavity mold, it is common to see the like cavities positioned diagonally to one another. For example, one left-hand part is molded in the upper left corner of the mold and the other in the lower right corner with the right-hand components in the other corners. This approach is used to balance material flow or to simplify gating, but it does create problems when it comes to automation.

7. Use mold locators.

Be generous in the use of mold-locating features. A center sprue bushing is enough to center the mold on the platen, but even a torpedo level is not accurate enough to ensure the mold is perfectly plumb and level. If a mold is not remounted exactly the same way every time, it may be necessary to reprogram critical robot positions to ensure proper operation, or you may need to reposition the mold. In either case, these adjustments increase mold changeover time and impact productivity.

8. Design the sprue and runner with gripping in mind.

In most cases, the robot is going to need to grip not only the parts but also the runner. So, the moldmaker must include features in the sprue/runner system that the robot can grip. Options can be as simple as using a one-inch-long sprue or building one or more vacuum pads (half-inch circular pockets along the length of the runner), which are inexpensive vacuum cups on which the EOAT can latch. Although both options yield a nominal increase in runner material waste, molders will see the return on investment in reliable runner removal.

How do moldmakers decide if they should implement cobots?

Companies should approach the question of whether to use cobots in the same way they approach other business decisions. Cobots can provide tremendous value, but their implementation necessitates proper application. For example, companies need to consider whether the cobots would have jobs that bring the cobots near humans, jobs with smaller payloads or jobs without high-speed cycle time requirements. Do not get caught up in the hype. Evaluate the bottom line, and consider both direct and indirect costs and benefits.

When determining the ROI, be sure to identify the objectives of the project first. The objectives could be both qualitative and quantitative, but even the qualitative ones should have value associated with them. For example, are you looking to reduce costs, improve productivity or increase product quality? These can all be assigned a metric. Offset the benefits with the true cost of implementation, which includes the initial purchase, reduced throughput, labor impact and cobot lifespan. Remember that businesses make good investments when they have a strong understanding and definition of expectations and costs.

(Source: The True Cost of Cobots)

What do moldmakers need to know to maintain and upgrade robots?

Designate a leader. From organization to execution, an ultimate decision maker should manage every aspect of robot maintenance. Also, in the event the scope of a project should veer off course, this designated leader can intervene to make tough decisions.

Follow best practices. Technicians should consider past lessons from previous maintenance sessions and ensure any repair or upgrade is consistent with current manufacturer recommendations. Similarly, give any technicians who will be responsible for maintenance or repair the proper training and tools to complete the job. In preparation, employees may benefit from robot training and a web-based robot maintenance system.

Deploy a smart inventory strategy. To prevent downtime or to avoid costly lead times, technicians should determine parts to order and have on hand. Common items to keep in stock are gaskets, gasket covers, connectors, seals, cables, teach pendants, gear oil, grease for bearings and controller batteries or air filters. To determine when future parts may be necessary, leading manufacturers heavily rely on software-based data collection and visualization tools that visually display the status and health of factory equipment in real time.

Perform a grease analysis. Because well-lubricated robot axes help control friction, vibration and heat, manufacturers should periodically check and re-grease each axis with the recommended OEM grease. Doing this helps maintain proper levels of viscosity in the grease, often preventing costly repairs. While some buildup of ferrous naturally happens, a spike in the content of one or more axes can hint that there is a potential problem with the drive.

Schedule a “holiday shutdown.” While the words “holiday shutdown” may induce panic throughout some organizations, many companies have embraced the concept, where a skeleton crew performs robot upgrades, preventive maintenance and process improvements during a designated period. Because time is limited, management should communicate in advance specific goals with achievable steps. This plan should list the projects to be done, state who is responsible for each task and give a detailed logistical workflow. Also, any external contractors required to help should be scheduled six to eight months in advance.

Meet with an OEM technical manager. Whether your organization will be taking on the responsibility of regular maintenance or an annual shutdown, a planning session with a technical manager from your robot OEM is suggested. Open communication with an expert can guide technicians in emergency situations, as well as aid in executing a successful overall strategy.

Look to the future. While robots have come a long way, they still require regular maintenance to ensure peak performance, maximizing ROI. When the team addresses any issue, the designated leader should record the procedures that worked and what did not. Regardless of the revelations, every employee should be proactive in managing risks for future success.

(Source: How to Maintain and/or Upgrade a Robot)

.png;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)