Ultrasonic Cleaning Equipment Cleans all Mold Sizes

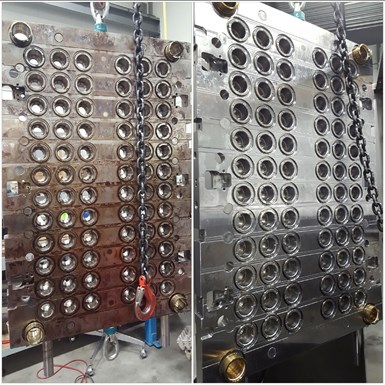

Fisa North America brings nonabrasive cleaning to the mold maintenance forefront, removing oil, grease, colorants, gassing and more in as little as 20 minutes.

With over 40 years in the industry, Fisa North America continues to strive to bring ultrasonic cleaning to the forefront of mold maintenance with its design and manufacture of ultrasonic cleaning machines and offered turnkey solutions. Ultrasonic cleaning helps eliminate the rigorous manual labor and abrasive cleaning methods by providing nonabrasive cleaning to remove oil, grease, colorants, gassing, etc. in as little as 20 minutes. Because of Fisa’s Magnetostrictive transducers, the company can manufacture any tank size, providing customers the capability to clean the largest molds.

Moreover, Fisa offers in-person validation trials at its lab demo facility, so prospective clients either investigating ultrasonic cleaning, or just discovering the technology, have an opportunity to view the benefits firsthand.

Fisa offers a complete range of standard and custom-built machines. The VST ultrasonic cleaning line, for example, contains several standard-sized models based off Fisa’s experience and market demand. The VST150 model offers the capability of cleaning molds/plates measuring up to 20" × 20", and has the option to load up a basket with components such as pins, slides and inserts.

Related Content

-

How to Map Mold Water Circuits

Prevent mold damage and maintain consistent part quality by using a mold mapping system that ensures consistent turbulent flow.

-

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.