Synergetic Enhances Mold Design Software Ease of Use

Amerimold exhibitor highlights new developments for its XMD mold design software to eliminate extensive training requirements for new users.

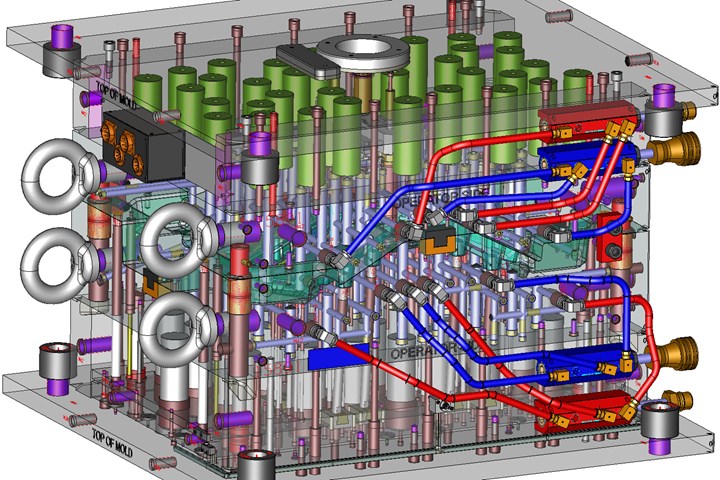

Photo Credit: Synergetic Eng & Manufacturing Services

Synergetic Eng & Manufacturing Services says its current focus in the development of XMD, an automated, knowledge-based mold design solution, is on ease of use. This has been achieved, the company notes, through the continuous leveraging of its intelligent automation technologies, with a conscious effort to afford all the advantages XMD offers to new users, and less experienced designers, such as eliminating extensive training requirements to be able to use the software.

New features have been added to XMD further demonstrate these objectives, including enhanced Relational Mold Base updates, and completely re-engineered Scope controls for precision control of changes. The company also notes several new products launching within XMD with the XPM - Expert Part Manager, XHR - Expert Hot Runner and several others.

Overall, XMD draws, manages, understands and checks hundreds of mold design details and has been developed to further increase the efficiency and accuracy of the design and manufacturing process.

The company will be showcasing XMD and its other solutions at Amerimold 2021 in September.

Exhibitor: XMD - Expert Mold Designer - Synergetic Eng & Manufacturing Services

Booth 130 (P)

Related Content

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)