Standalone Software Enhances Visual Defect Detection

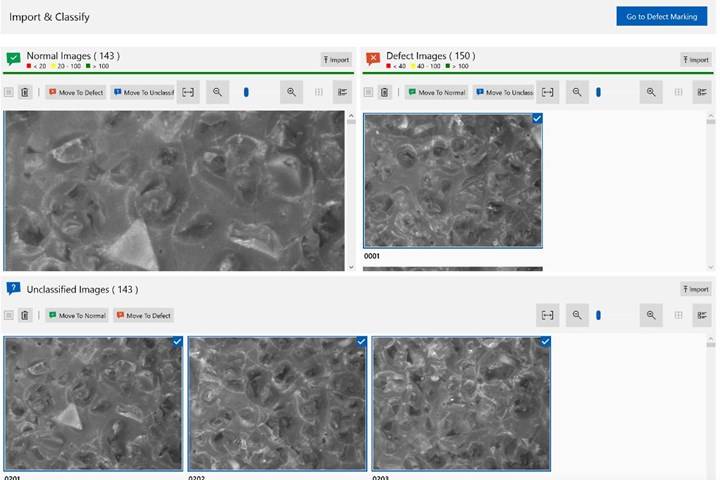

Mitutoyo’s AI Inspect program enables operators to leverage AI-enhanced modules for visual defect analysis.

Photo Credit: Mitutoyo America Corp.

Mitutoyo America Corp. has added AI Inspect to its software lineup. Mitutoyo AI Inspect is a standalone software product designed to assist customers with next-generation visual defect analysis across multiple applications.

The software’s headlining features are the distinct Training Module and Runtime Module. The first of these enables users to develop inspection routines for automated implementation of defect detection using image sets, while the Runtime Module incorporates these inspection routines into the system.

The Training Module’s methodologies include importation, organization and storage of user-defined inspection projects; integrated tool sets and techniques for loading and classifying normal and defect image sets; an interface that enables the operator to mark and highlight defects on images; a section that enables operators to account for brightness, noise and focus differences; an interface that updates the operator on the progress and success of the training sequence; and an interface that allows operators to review image, pixel and component predictions. Users deploy models with unique identifiers for added clarity.

Mitutoyo AI Inspect’s Runtime Module includes an inference testing application for reviewing the AI model with sample testing on new images.

Related Content

-

How to Achieve Automated Measurement With Advanced Touch Probes and Laser Systems

A combination of lasers, probes and software help moldmakers automate in-process cutting tool and workpiece measurement.

-

How to Quickly Check Cooling Channels

Smart hole inspection validates possible leakages and strangulations in the cooling channels by doing tightness and flow rate tests.

-

Quality Verification of Machine-Ready Blanks With CMM

TCI Precision Metals highlights the installation of the newest Keyence model XM-5000 handheld probe coordinate measuring machine (CMM).