Profile Milling Cutter Delivers Precision Machining, Optimized Tool Life for Molds

The new Walter USA Xtra·tec XT M5460 offers precise, cost-effective machining and optimize surface finishes for mold and die making, aerospace and energy industries.

Share

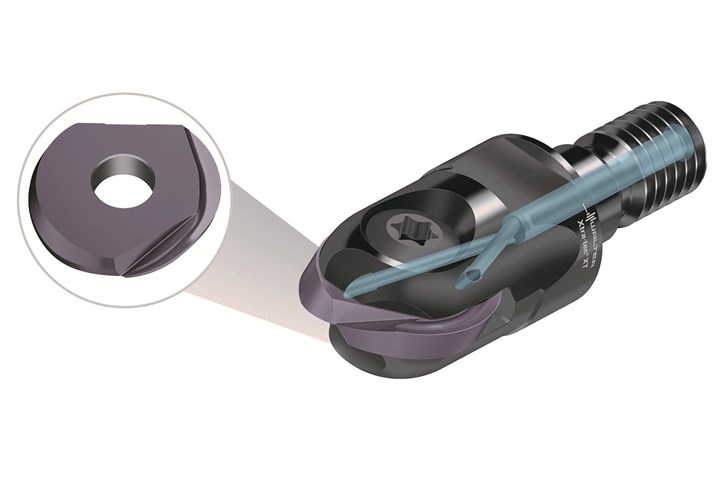

Walter USA introduces the Xtra·tec XT M5460, a new profile milling cutter that delivers maximum precision, tool life and surface quality in precise machining of freeform surfaces and deep cavities such as molds.

The Xtra·tec XT M5460 has been specially designed for difficult materials, particularly for hard machining of steels up to 63 HRC. Alongside the geometries of Walter’s P3201 and P3204 indexable inserts, the company is now offering these inserts in its newest grade, WHH15X, for hard machining. In field tests, the M5460 with this latest grade reportedly achieved increases in tool life of up to 500%. The profile milling cutter is said to be effective in steels (ISO P), cast iron (ISO K), stainless steel (ISO M) and hard materials (ISO H). In addition to mold and die making, the product also offers advantages for the aerospace and energy industries.

Moreover, the profile milling cutter now also provides an internal coolant channel, enabling chip evacuation using compressed air or MQL. This is necessary for deep pockets, Walter points out.

Walter offers the Xtra·tec XT M5460 with both Weldon and cylindrical shanks, as well as with the industry-standard cylindrical modular interface. The company is initially launching the milling cutter for diameters: 3/8-1" and in metric from 8-32 mm.

Related Content

-

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

_300x250 1.png;maxWidth=300;quality=90)