Next-Generation Advanced Hot Runner Technology for Precision Molds

Westfall Technik’s team is passionate about eliminating cold runners from injection molding applications, making this possible through its specialty MHS Hot Runner systems and technical staff.

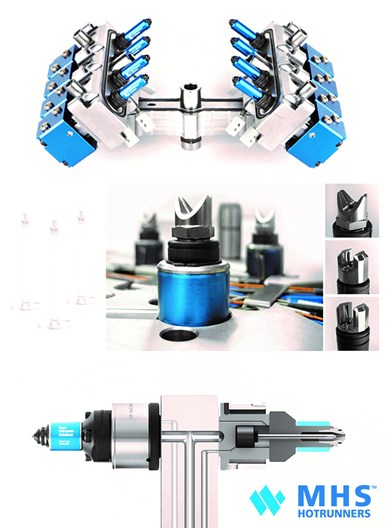

Photo Credit: Westfall Technik

Westfall Technik’s MHS Hot Runner systems are designed for reliability and longevity in order to mass produce billions of precision-molded parts. Westfall says its hot runner solutions are designed to withstand a wide range of pressure and temperatures, and are capable of running materials from polypropylene (PP) to polyetheretherketone (PEEK), and polyvinylidene fluoride (PVDF) to bio-absorbable resins, with shot sizes that range from 1 mg to 400 Ibs.

Westfall’s team of hot runner experts are passionate about minimizing cold runners in injection molding applications and have developed several solutions to direct gate complex parts, such as angled valve gate nozzles, internal side gate nozzles, internal valve gate nozzles and dual and multi-tip nozzles. Westfall’s team also developed hot runner manifolds that move during the cycle to gate through slides. The final frontier was direct gating micro parts, which Westfall says it achieved by developing a new Isokor molding process and M3 hot runner technology.

Westfall’s team of hot runner experts, designers and technical support staff collaborate with OEMs, toolmakers and molders to deliver high-performing, innovative molding solutions available in the industry. According to the company’s chief commercial officer, Westfall enables its customers to push boundaries of injection molding, while simultaneously improving part quality and reducing productions costs.

Related Content

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

_970x90 1.png;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)