New Component Options Made Available to Parametric Native CAD System

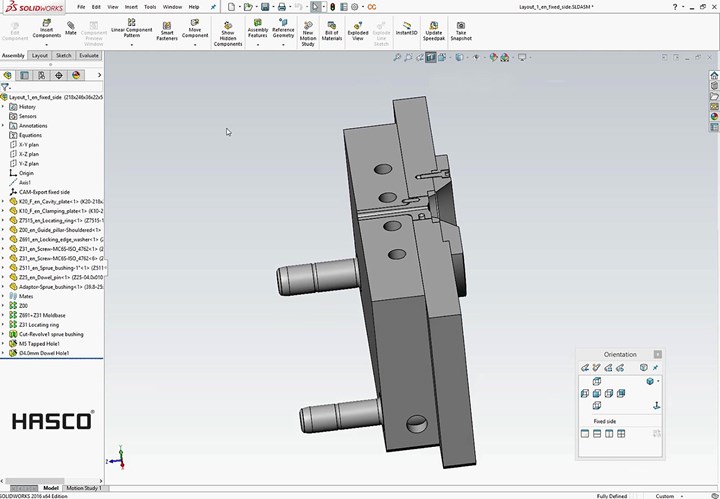

Around 100 new Hasco products are available for SolidWorks mold designers to use for the generation and configuration of molds.

With the latest update of its SolidWorks database, Hasco is providing its moldmaking customers with an exclusive tool that now includes approximately 100 additional products. The comprehensive parameter-controlled native CAD system for standard mold units offer designers several advantages, the company notes, including simple and precise working (see “Fully Parametrized Native CAD Databases Reduce Design Time, Maximize Process Reliability” for more information).

In addition to the geometry of the component, the database’s standard elements also contain information about the cutting geometry. Through Boolean operations, the cutting elements can be removed from the mold plates. Hasco says this considerably facilitates the installation of mold units in the mold.

The fully parametric data also gives an advantage if any changes are made, since relevant parts automatically adapt to the corrections. A new parts list is then generated, guaranteeing high process reliability and eliminating the risk of incorrect orders. The largely automated ordering process ensures punctual delivery for the start of assembly.

In addition, if the design data — with the added value of the installation geometry — is channeled directly to the machining center, Hasco claims that further savings can be made at the CAM stage downstream.

Hasco’s CAD specialists are available to assist SolidWorks users implementing the database into their own systems.

Related Content

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

-

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

.jpg;maxWidth=300;quality=90)