Indexable Thread Mill Demonstrates Universal Metal Cutting

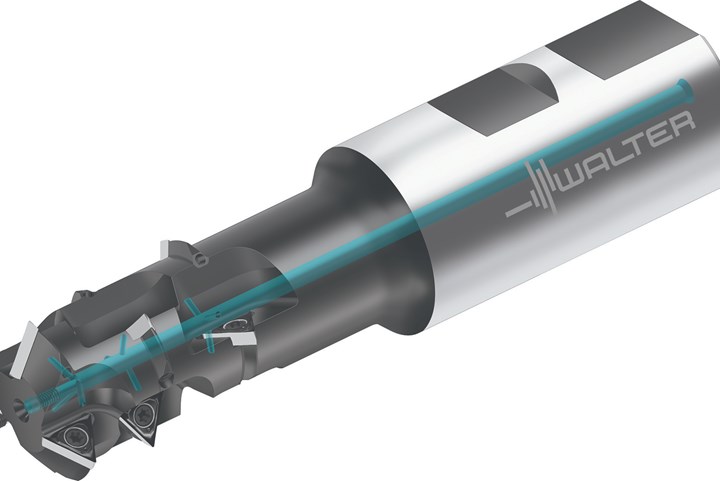

T2710 indexable thread milling cutter brings high productivity, reliability and quality to the machining of short threads.

Photo Credit: Walter USA

Walter’s launched T2710 indexable thread mill is reported to bring higher levels of productivity, reliability and quality to the machining of short threads. This multiple-row cutter is designed for high-cutting speeds and high feed per tooth, with an indexable insert boasting three cutting edges, all of which results in low cost per thread.

T2710 inserts feature WSM37S, a wear-resistant universal grade, and defined corner radii for standard threads. The cutter’s small space between rows facilitates quick machining of short threads. Process reliability is also enhanced by easy handling with few radius corrections. Walter says excellent thread quality is enabled by operational smoothness, so the threads are free of chip residue. It also has variable radial or axial coolant supply.

According to Walter, the T2710 indexable thread milling cutter can be used universally in steels, stainless steels, cast iron, non-ferrous metals, high-temperature alloys and hardened steels up to 55 HRC. It machines threads with nominal diameter from 0.79" (20 mm), and pitch range of 1.5-6 mm/18-6 TPI up to 1.5 x Dn thread depth. The tool is supplied with a Weldon shank for rigid and secure clamping. A version of the T2710 indexable thread mill insert, with anti-vibration land for unfavorable machining conditions is also available. This geometry is listed as “D61.”

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

.png;maxWidth=300;quality=90)