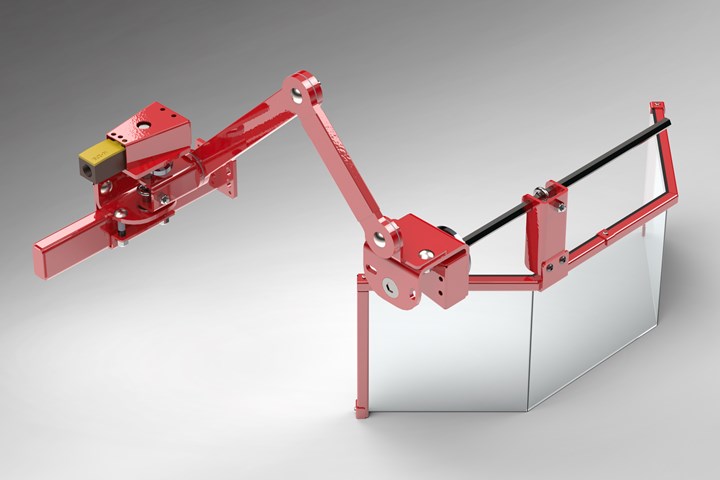

Face Shield Safeguards Against Machining Equipment

The Rockford Systems’ Protector Shields defends operators from flying debris, lubricants, coolants and swarf from cutting and turning machines.

Photo Credit: Rockford Systems

Rockford Systems’ Protector Shields safeguard against mills, drills, lathes, grinders and other cutting and turning machines. Constructed of 14-gauge, powder-coated steel and thick 3/16” shock-proof, scratch-resistant polycarbonate, Protector Shields are said to defend operators from flying debris, lubricants, coolants and swarf. An LED light incorporated into the frame also illuminates the work area for improved visibility; some models may feature color-changing options, to help indicate when the shield is open or closed.

For additional protection, an interlock will disengage power and prevent a connected machine from starting up when a Protector shield is not in the correct work position. An optional safety monitoring relay can also be added to monitor the interlock switch for failure or damage.

Rockford Systems’ Protector Shields Series are modular in design so that shape, size, mount, arm, offset, lighting, interlocking and safety monitoring can be configured according to specific machine needs.

Related Content

-

Kitting Cart Enhances Material, Component Handling Capacity

The Creform System features a custom five-level shelf section with pullout drawers to easily and safely transport materials, components and other devices through a warehouse or facility.

-

Industrial Drive Technologies Support Moving, Rotating Molds of All Sizes

RUD Tecdos solutions within its Mold Handling Solutions portfolio manage horizontal, vertical and rotational drive solutions for all environments.

-

Mold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

_300x250 4.png;maxWidth=300;quality=90)