Industrial Drive Technologies Support Moving, Rotating Molds of All Sizes

RUD Tecdos solutions within its Mold Handling Solutions portfolio manage horizontal, vertical and rotational drive solutions for all environments.

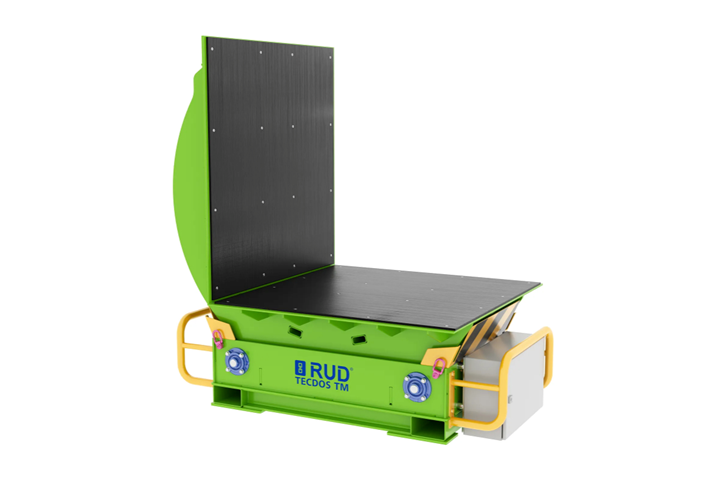

The RUD Tecnos TM. Photo Credit, all images: RUD

RUD Ketten Rieger & Dietz GmbH u. Co. KG manufactures sling technology, lashing technology, anti-skid chains, hoist chains, conveyor and drive systems as well as tool handling equipment. With its Mold Handling Solutions product portfolio, the company aims to solves mold handling challenges by saving time and improving the safe handling of molds.

The company points to examples such as the RUD Tecdos TMB workbench with turnover device and the Tecdos TM turning table. The Tecdos TSB manual tool opener, and the Tecdos TS electrical tool separator are an ideal complement for separating and closing tools.

RUD Tecnos TMB.

The Tecdos TMB industrial workbench makes it possible to rotate objects and maintain molding forms and objects that are up to 5,500 pounds (2.5 tons) with a cordless screwdriver, for a variety of mold types and sizes. Moreover, its low-weight, compact form enables engineers to work on more than one mold at a time. The Tecdos TMB is ideal for injection molding, mold manufacturing, aluminum die casting and packaging materials.

The Tecdos TM turning table is also well-suited to moving heavy molds and bulky items; up to 140,000 pounds can be turned, rotated and tilted flexibly. Since it is not anchored to the floor and it’s compact, Tecdos TM can be moved with a hoist (lifting points) or lift truck (fork insertion points). Its low supporting surface enables engineers to clean the open tool directly on the table.

Related Content

-

New Tool Breakage Alarm System Mitigates Machining Damage

If a cutting tool breaks or compressor malfunctions the Tool Breakage Alarm from Air Turbine Tools alerts operators, or stops the program altogether.

-

Mold Solutions Target Safety, Storage and Productivity

NPE2024: Globeius and its suppliers showcase solutions focused on decreasing downtime, reducing energy consumption, increasing safety and more in an injection mold shop.

-

Machine Tool Breakage Detector Enhances Mold Manufacturing Reliability

Heidenhain’s new TD 110 is a fast, contact-free, in-process gage that can quickly inspect drill bits and end mills, even while spinning at their operational speed.

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)