End-to-End Conformal Cooling Design, Production for Faster Cycle Times, Boosted Part Quality

Cimatron works with moldmakers to design and optimize molds with conformal cooling, prepare it for an accurate print and ensure complete post-processing.

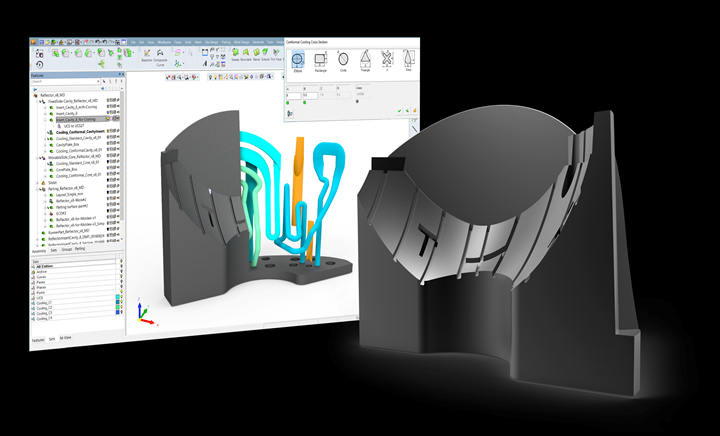

Photo Credit: Cimatron

Cooling is a critical process for plastic injection molds, affecting both cycle time and final part quality, Cimatron notes, but is especially challenging for complex parts when using traditional drilling and milling methods. To avoid longer cycle times, warpage and sink marks on the part, the company presents its intelligent conformal cooling channel design for faster cycle times, better part quality and a more efficient cooling process.

Cimatron’s end-to-end solution reportedly enables moldmakers to detect areas that would benefit from conformal cooling channels, from using its dedicated toolset to design the mold with an optimal combination of conventional and conformal cooling channels, to preparing the mold component for 3D printing and post-processing. Cimatron’s conformal cooling solution is also available as a standalone seat that can work alongside other mold design systems.

According to Cimatron, the car reflector headlight example above demonstrates how its conformal cooling solution reduces injection molding cycle time and significantly improves part quality including:

- Cycle time reduction by 17% (from 40.3 sec to 33.4 sec).

- Warpage reduction by 62%.

- Part temperature deviation reduced by 73%.

- Sink mark affected areas reduced by 50%.

Related Content

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking enabled the speed necessary to iterate to a solution.

-

Building Molds: Most Popular Reads of 2024

Dive into the most-viewed content for building your mold, including topics such as cutting tools, EDM, hot runners, additive manufacturing, mold materials, machining and mold components.

-

MMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.