Contaminant-Blocking Filter For Hot Runner Systems

INCOE Corp.’s SPM filter traps foreign particles prior to entering the hot runner manifold, which the company says enables trouble-free processing and superior part quality.

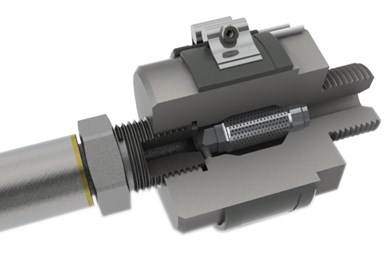

INCOE's SPM filter and XRN machine nozzle. Photo Credit: INCOE Corporation

INCOE Corporation says molded part quality and superior gate cosmetics require minimal gate sizes. Any contamination in the molten plastic can plug the orifice of the hot runner nozzle gate and stop production or yield unacceptable parts. To avoid this, INCOE’s SPM filter traps foreign particles prior to entering the hot runner manifold, which the company says enables trouble-free processing and superior part quality.

The filter element design contains tapered holes to trap contaminants while enabling molten plastic flow at minimal injection pressure loss. According to the company, this minimally restricted flow through design feature is unmatched in the industry.

The SPM filter assembly is threaded to the injection molding machine barrel. Designed with convenience in mind, maintenance of the SPM filter is said to be intuitive. Foreign particulate (ferrous or non-ferrous) is trapped by the filter element, and when an increase in injection pressure is realized, the filter element can be cleaned while still threaded to the injection molding machine barrel. INCOE says that after removing the machine nozzle with tip, the filter element plug is accessible and easy to remove with the use of a custom INCOE-provided socket. Contaminants are then purged out through the filter element using screw rotate.

Related Content

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

.jpg;maxWidth=300;quality=90)