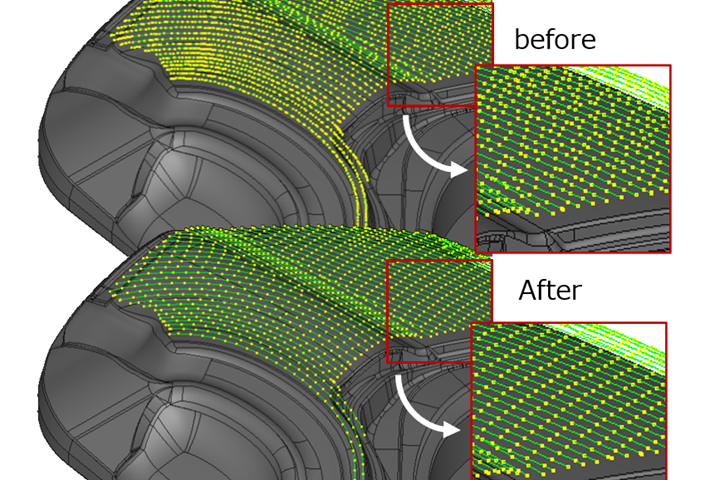

CAD/CAM System Competent Point Rearrangement Function for Optimal Surface Finish

Known for its high-accuracy, surface-based CAM calculation engine, CAM-Tool’s new function provides smoother toolpath cutting points and machine template customization.

Photo Credit: CAM-Tool, CGS North America.

CAM-Tool by CGS North America has added the competent point rearrangement function to its toolpaths. This has been added into the profile calculation condition window to give users another tool to achieve optimal surface finish.

According to CGS North America, the CAM-Tool is known for its high-accuracy, surface-based CAM calculation engine which generates points directly from the model surfaces instead of using the triangulation mesh that a majority of other CAM systems use.

With the addition of the component point rearrangement function, this reportedly enables users to smooth toolpath cutting points further, ensuring complete NC code is being sent to the machine. The option to rearrange by either aligned or alternate arrangement type also allows the control to be adjusted exactly as desired in order to fit the machine. Overall, NC code helps machines run smoother and faster while achieving better surface finish and tool life, the company says. Having this built into the profile calculation condition window enables users to build their tested settings into their machining templates so they can set it once and apply to future jobs when needed.

Related Content

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

The In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.