Partnership Augments LSR Molding Simulation

Sigma Engineering and Momentive Performance Materials announce a cooperation to optimize material data for silicone elastomers to make LSR molding simulation more reliable.

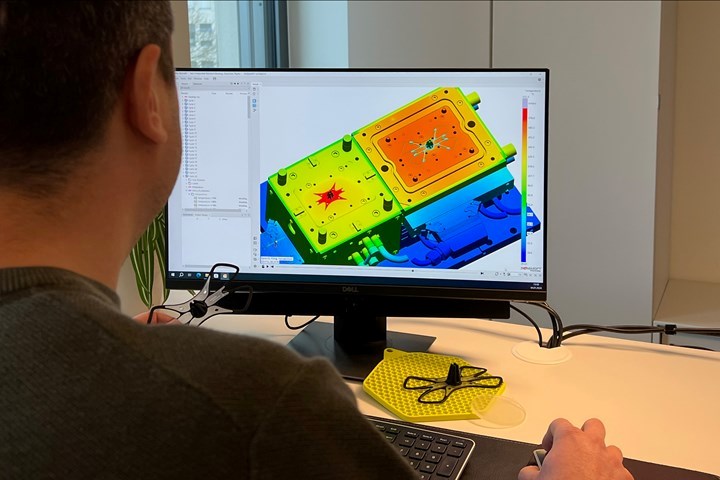

Sigmasoft Virtual Molding will apply silicone material data from Momentive to improve LSR injection molding simulation. Photo Credit: Sigmasoft

In an agreement between a provider of liquid silicone rubber (LSR) injection molding simulation and one of the top manufacturers of silicone and silicone derivatives, Sigma Engineering GmbH and Momentive Performance Materials are collaborating on an effort to use more precise material data to create more accurate simulation of LSR injection molding.

The companies note that the more precise the material data and understanding of the material, the better the predictions made by the simulation, adding that applying standardized laboratory values for the material properties can’t fully describe the complex behavior of components (watch “Benefits of Simulation to the Mold Builder, Molder”).

The companies say data from real injection molding processing is needed to refine and calibrate the material data and improve the reliability of the simulation results. Since 1998, Sigma Engineering has offered its simulation software, Sigmasoft Virtual Molding, to the plastics processing sector. The program combines a part’s 3D geometry with its tooling and temperature control system, while also integrating the parameters of the production process for more accurate simulations. Sigmasoft Virtual Molding has multiple process-specific models including 3D simulation of LSR molding.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

_300x250 4.png;maxWidth=300;quality=90)