The Evolution of Process Training for Mold Builders

Process training coupled with cavity pressure data provides mold builders with value and information that can be passed onto customers.

Remember John T. Parsons? He is credited with pioneering numerical control, the precursor to computer numerical control (CNC) in northern Michigan—the ubiquitous technology that makes moldmaking so sophisticated today.

The evolution and revolution of technology has made mold builders more sophisticated and resourceful; and, more so now than ever before—as the trying economy and outsourcing take their toll—mold builders are seeking out value-added services and competitive advantages. Sensor technology is one such area.

In regards to cavity pressure, mold builders are starting to incorporate sensor technology as never before. It wasn’t too long ago that cavity pressure sensors were seen as just another request from the customer, but today they are becoming a valuable tool in providing a robust product for the customer.

Sensor History

Cavity pressure sensors are not a new technology in the realm of injection molding. They have been around since the sixties. They come in several different types, shapes and sizes—from indirect sensors, which are installed behind an ejector pin to direct sensors that are mounted flush with the cavity. The appropriate cavity pressure transducer will be dictated by the application. With the help of new sensor technology and solid modeling, sensors have gone from being delicate and difficult to install to robust and straightforward.

However, it has only been in the last 10 to 15 years that cavity pressure has been embraced by injection molders. For the mold builders, it has only been in the last five years. The wealth of information that has been realized and applied to mold design and manufacturing, is growing in the mold building community.

The Right Data

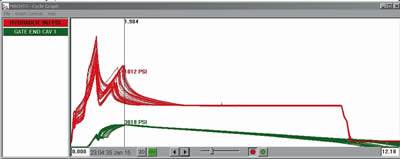

By installing cavity pressure sensors in molds, mold builders gain precise and abundant information as to how the tool is performing under rigorous processing conditions. An example would be testing for cavity balance at multiple fill speeds to see if different shear rates change the balance and to what effect.

Cavity pressure data also can provide information on cooling and shrinkage. What effects do different melt and mold temperatures have on the outcome of the part? All of which can be used to provide the mold builder with information to improve the mold and its ability to provide a quality part.

So, you’re thinking, “I already get that information with flow simulation software,” right? Have you ever compared cavity pressure data to flow simulation data?

Today mold builders have become more than just steel cutters. They have teams of engineers, designers and even processors. Process training for mold builders and tooling engineers has never been more popular. Process training coupled with cavity pressure data provides the mold builder with a wealth of value and information that can be provided to the customer.

Data Benefits

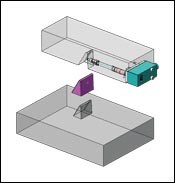

There are more than CNC machines humming away; now there are molding machines as well. Cavity pressure sensors are being installed in new programs with the help of data acquisition to provide information as to the robustness of the tool on which the customer has just spent thousands of dollars. Trialing the molds in house allows mold builders to accomplish rework faster, and with data gained with cavity pressure, pinpoint particular areas for improvement.

With the aid of solid modeling, cavity pressure sensor models can be e-mailed or downloaded by the mold builder and designer and then dropped into the initial design instead of as an afterthought. This makes the installation and application more robust and helps eliminate the return of a tool due to the sensor being installed improperly. It also allows the mold builder to identify potential problems, such as water lines that may be blocking the installation.

Being able to identify these in the design stage allows ejector pins to be relocated or added to allow for a more robust installation or to select a more appropriate sensor for the application. Designing the installation on the front end is always cheaper then reworking the tool.

Summary

As molds and processes become more sophisticated, the installation of cavity pressure sensors follows that trend. More sensors will be installed for controlling valve gates and core movement sequences. They also will be installed in moving slides and cores at less than ideal angles, where the resultant movement creates situations in which cables can be chafed or pinched. Another rising trend is the installation of cavity temperature sensors—providing another source of information for cooling and melt front detection.

With today’s mold builders seeking out value-added services and competitive advantages, cavity pressure transducers can play an

integral part in your shop’s strategy and success.

Related Content

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read More30 Under 30: The Next Generation Reshaping Moldmaking

Young professionals are bringing new perspectives, technical skills and strong commitment to the moldmaking industry. MoldMaking Technology recognizes these individuals through our 30 Under 30 program, highlighting emerging talent helping to shape the future of precision manufacturing.

Read MoreRead Next

Setting Up a Robust Process Forever

Deciding how to process a product with the least amount of part variation over the long term.

Read MoreOvercoming Pain Points in Moldmaking with AI

Shops that embrace AI as a tool, not a threat, can enhance efficiency, preserve expertise, and attract tech-savvy talent.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More