Spring has finally made its appearance, and with it, a wide range of new/proven products! This technology roundup covers machining, cutting tools and EDM technologies. From clamping systems for CNC machines, thread grinding machines and enhanced vertical machining centers; a wire EDM module to streamline programming and a rotary EDM to reduce PCD tool cycle time; and solid carbide five-flute end mills, new exchangeable-head drill insert grades and stainless steel cutters, the available options for the moldmaking industry are endless.

Expect to see upcoming machining, EDM and cutting tool products not mentioned here published for the next few weeks under the “New Tech” section on Moldmaking Technology’s website.

Our last technology roundup covered mold component, machining and hot runner companies. View them here, or find them in MMT’s April 2021 issue.

Machining

With a focus on Industry 4.0, GF Machining Solutions now offers North American manufacturers the Open Platform Communications (OPC) Unified Architecture (UA) interface Version 1.0 as a single connectivity solution. The standard, developed by the OPC Foundation as a robust, cross-platform interface, provides a common communication language across GF Machining Solutions products, technologies and services, enabling easy connection to existing enterprise resource planning (ERP) systems and a wide range of other manufacturing solutions. GF says this offers users seamless data exchange for the collection and assembling of personalized key performance indicator (KPI) measurements at every level of operation, simplifying efforts to optimize processes.

The Liquidtool Manager, offered by Liquidtool Systems, a a sister company of Blaser Swisslube AG, is an intelligent, IoT-based solution that combines plug and play (PnP) technology for automatic, easy and reliable monitoring of coolants conditions. Said to be the first of its kind, Liquidtool Manager integrates a magnetically mounted sensor, which is connected to a company’s WLAN or LAN internet connection and operated with the corresponding app via tablet, smartphone or PC, to alert operators to changing coolant tank conditions. Liquidtool Systems says its system enables companies in the metalworking industry to further achieve digitization and Industry 4.0.

The HCN-6800 NEO from Mazak’s HCN Series of horizontal machining centers (HCM) has received several upgrades in terms of efficiency and ease of use. It features a fully redesigned enclosure, standard and optional equipment and improvements throughout the machine for a wider range of part-production applications, reduced cycle times and floor space requirements, increased maximum part and tool capacities and streamline automation.

In accordance to a conducted spindle load analysis for fluting operations, ANCA Inc. has upgraded the FX5 Linear two-wheel pack machine with a new grinding spindle rated at 12 kW peak power, and also released a 19-kW high-powered spindle option. The company says these spindle options match the grinding spindle fitted to the FX7 machine with six-wheel packs, making the FX5 suitable for a more industrial environment.

NSK America Corp. has introduced its electric iSpeed5 System, a fully tool-changeable, high-speed motor/spindle meant to increase machine tool speed.

The 60,000- or 80,000-rpm, 350-watt, brushless DC system is said to eliminate the need for any operator intervention via a connection under the machine spindle that can prevent coolant, chips, dust and other machining debris from contaminating the stop block. High-speed and micro machining for both short or long periods of operation, as well as lights-out manufacturing are possible.

Mazak continues its i-H Series rollout with the Integrex i-200H ST Multi-Tasking Machine. Like other Integrex i-H Series machines, Mazak says, the Integrex i-200H ST features a new design that increases flexibility and enhances machine performance for easier automation integration and the ability to process a variety of part types without additional expenses.

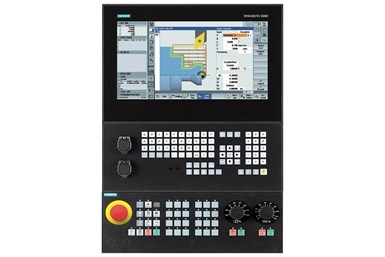

Siemens Corp. now offers its mid-range CNC machine, the Sinumerik 828D, with a version 4.8 operating system, which extends the array of hardware and software solutions for its integrated Sinumerik portfolio. This includes integrated industrial software and automation technology for full productivity potential in mid-range control.

Sinumerik 828D is a compact, panel-based CNC, offered in vertical and horizontal models for flexible machine design integration.

Heidenhain introduces smarter and faster versions of its RCN absolute angle encoder series for use in machine tools requiring high speed, accuracy and contamination resistance. The new models, RCN 2001, 5001 and 8001, are said to be particularly useful with fast rotating axes and direct-drive motors because the permissible speeds are up to three times higher than older, established RCN encoders. Aerospace, medical and turning applications, which require highly accurate positioning and high speeds are made possible.

The Mazak Integrex i-630V AG Hybrid Multi-Tasking Machine combines full five-axis milling, powerful turning operations and pallet-changing capabilities, enabling shops to add gear cutting to their part-processing repertoires and eliminate contracting out such work. It is built on the Integrex milling and turning platform and performs gear milling, hobbing and skiving via its Smooth Gear Cutting software suite.

Mitsui Seiki’s GSH 200A Thread Grinding Machine combines flexible application, high processing speeds and consistent precision to complete an extensive selection of threading jobs. The GSH 200A is said to be engineered to handle a wide variety of workpiece sizes. Maximum diameter swing over the machine table is 480 mm and distance between centers is 2,250 mm, enabling the machine to grind a maximum screw length of 2,000 mm and maximum workpiece diameter of 200 mm.

To further enhance customer benefits of its machine rebuild and remanufacture services, United Grinding North America now offers customers with older Walter Helitronic Power Series tool grinding machines the option of new advanced automation technology seamlessly retrofitted as part of a machine rebuild. The option replaces original gantry beam-type loaders with faster, more productive FANUC LR Mate 200i robots, the same as are featured on brand new Walter Helitronic machine models.

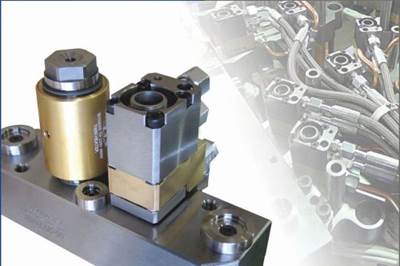

Roemheld North America’s PC 80 Clamping System for CNC machines is a manual vise that comes in two styles, fixed jaw and self-centering. It features a simple, rigid, all-steel design, and includes clamping jaws with a dovetail-shaped serrated gripping feature that can be quickly reversed or changed out. The vise can hold round inserts, enabling cylindrical parts or billets from 44-95 mm in diameter to be clamped securely.

The Mazak Variaxis i-800 Neo Vertical Machining Center is said to offer shops an enhanced version of a popular five-axis machine, with a powerful CNC, faster machining cycle times, expanded workpiece capacities and more automation options.

Among the primary enhancements on the Variaxis i-800 Neo is the Mazatrol SmoothAi CNC. It features such functions as Smooth Machining Configuration (SMC) for process optimization with real-time operator control of a wide range of cutting parameters and Ai Thermal Shield for stable machining accuracy.

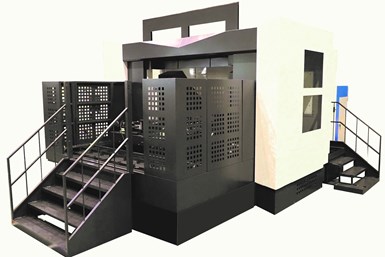

New to Niigata Machine Techno USA’s heavy-duty HN-5X series, the HN80E-5X 5-axis horizontal machining center features 49.2, 48.4 and 47.2 in. of travel in the X, Y and Z-axes respectively, and allows a maximum workpiece diameter of 49.2 in., a height of 39.4 in. and weight of 3,300 lb. Incorporating the solid cast iron X and Z base of Niigata’s HN100D-II Heavy Duty Boxway horizontal machining center, the HN80E-5X provides maximum rigidity, stability and accuracy.

Siemens Digital Industries Software says it is driving forward digital transformation in the machine tool industry with Sinumerik One, a digital native CNC system. Offering seamless integration of hardware and software, machine tool builders can virtually map their entire development process, reducing the product development phase and time-to-market for new machines. Further, Siemens says Sinumerik One enables machine concepts and functions to be discussed and planned before hardware is available.

Initially launched by iTSpeeX LLC in 2018, Athena, said to be the first voice assistant for the manufacturing industry, has been designed to help machine tool builders provide more productive and efficient equipment to manufacturing companies. Further, Athena is meant to help solve skilled labor shortages.

Siemens Digital Industries Software has launched three technology packages exclusively for its Sinumerik One CNC control system. The Sinumerik One Dynamics packages are available in three different variants: One Dynamics Operate, One Dynamics three-axis milling and One Dynamics five-axis milling. The software functions contained in each technology package are said to support users from machine-oriented programming in the job shop to high-performance machining of CAD/CAM-programmed workpieces with high surface quality.

Initially launched by iTSpeeX LLC in 2018, Athena, said to be the first voice assistant for the manufacturing industry, has been designed to help machine tool builders provide more productive and efficient equipment to manufacturing companies. Further, Athena is meant to help solve skilled labor shortages.

Mazak has launched the Ez machine series, the Mazatrol SmoothEz control and the accompanying MazakUSA.com/Ez website. The new machine family and control were developed specifically to help remove the cost barriers to acquiring the latest manufacturing technology without sacrificing machine capability or production performance, while the Ez website is to further streamline the customer experience and offers visitors focused access to Mazak’s newest product line.

EDM

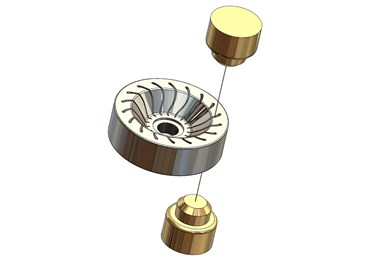

HCL Technologies (HCL) announces a new wire EDM module for the CAMWorks suite of CAD/CAM software. The wire EDM module includes new functionalities that takes the design model to G-code in one click. Once the user clicks the “Solid to G-code” button, the system automatically searches the part for machine-able features, identifies them, generates all the operations with the users’ preferences and settings (including tool offsets, cutting conditions and start holes), creates the toolpaths and posts the G-code.

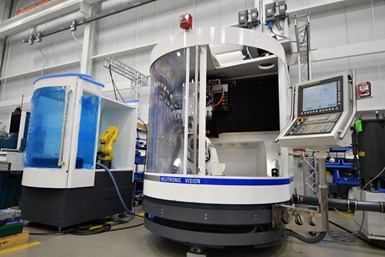

The ANCA EDG (Electro Discharge Grinding) is a high-performance rotary EDM machine platform has been refined to maintain the optimum spark erosion gap for both simple 2D- and complex 3D-path interpolations via Intelligent Adaptative Control (IAC).

IAC is an in-time, servo-controlled feature that automatically monitors and controls the erosion gap distance, in-process. Alternately, the Adaptive Spark Control (ASC) feature avoids over-eroding materials.

Cutting Tools

Dormer Pramet has launched a new generation of solid carbide five-flute end mills, which target dynamic milling for general machining and die & mold applications. Dormer’s S7 assortment is said to cover a wide range of operations in a variety of steels, cast irons and difficult-to-machine materials, including stainless steels and super alloys.

Tungaloy America has added the AH9130 insert grade to its DrillForce- Meister line of exchangeable-head drills designed for hole diameters ranging from 20-41 mm (0.787″ to 1.614″).

AH9130, consisting of a PVD coating layer optimized for drilling applications with a dedicated carbide substrate, is the latest insert grade specifically developed to provide significant tool life improvements and more predictable wear patterns in holemaking applications of ISO P (steel), ISO M (stainless steel) and ISO K (cast iron).

Greenleaf Corp. presents the XSYTIN-360 line of high-performance solid ceramic end mills, to the global market. Ideally suited for machining materials in the aerospace, automotive, die & mold and power generation industries, the end mills combine Greenleaf’s phase-toughened XSYTIN-1 ceramic substrate with a cutting geometry that is said to offer ten times higher productivity, and more versatility. The strength of the material enables chip load applications similar to solid carbide end mills with higher speeds common to ceramic machining.

Dormer Pramet has made a new range of solid carbide end mills for aluminum and non-ferrous materials available under its S6 assortment, including three and four-flutes cutters, along with several smaller diameters to the existing two-flutes offer.

The S6 assortment, the company says, is particularly suited to precision and high-speed machining of aluminum and its alloys. All geometries are said to provide high-quality surface finish, making the range suitable for airframe assembly, automotive and die & mold applications, particularly for prototyping.

The Dormer Pramet stainless steel milling range offers users versatility optimal and productivity. Insert styles include OEHT (octagonal), REHT (round) and XEHT (wiper). The double-positive 45° milling cutter (S450E) design, for example, enables the same cutter body to be used with both octagonal inserts for face milling and round inserts for face/copy milling applications, as well as support internal coolant delivery.

Tungaloy America has expanded the turning and boring capabilities for its TungBore-Mini line with the addition of boring toolholders that accommodate its XOMU inserts.

TungBore-Mini is a multifunctional drilling and turning tool line that integrates the capabilities of drilling, OD and ID turning tools. XOMU inserts features a geometry incorporating a large inclination angle on the cutting edge that produces light cutting, compared with standard ISO positive turning inserts typically used for ID turning or boring operations.

The Dormer Pramet barrel-shaped S791 end mill offers efficient five-axis machining for aerospace and die & mold applications.

Providing high surface quality, and suitable for semi-finishing and finishing in steel, stainless steel, cast iron and super alloys, the company says the S791 cutter is the first design of its type within its range and includes a nose radius for fillet milling, plus a larger tangential form for curved and deep-wall surface machining.