SLIDESHOW: Technology Showcase, Inspection and Measurement

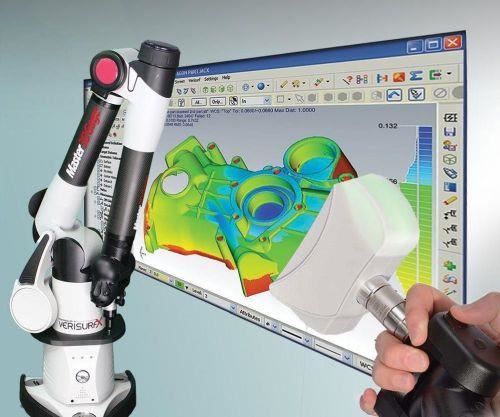

No matter what size moldmaking operation you may own or work at, you need inspection and measurement at critical stages of the process to drive efficiencies and profitability. So here are a few of the latest products we’ve heard about that you may also wish to see.

We all know that Moldmakers work with precision because customers expect their molded parts and products to work flawlessly in the way they intend them to. Moldmakers are still considered highly skilled craftsmen by many, but even they need to test and validate that molds and mold components are manufactured exactly right. Hence the use of many inspection and measurement devices, which is the focus of today’s Technology Showcase.

No matter what size moldmaking operation you may own or work at, you need inspection and measurement at critical stages of the process to drive efficiencies and profitability. So here are a few of the latest products we’ve heard about that you may also wish to see.

By the way, this topic is a good segue into MMT’s annual Leadtime Leader competition. If you haven’t already, please take a moment to click here and submit your application for 2017. We’ll announce the winners at Amerimold in Chicago. If you think your company is meeting and/or exceeding customers’ delivery demands, which inspection and measurement devices help you to do, then you are probably a good candidate for Leadtime Leader 2017! We hope to hear from you soon!

Related Content

-

2021 30 Under 30 Honors Program: Mentoring in the Next-Generation of Moldmaking Professionals

Young professionals are vital to the moldmaking industry, and it is important to acknowledge those making strides in shaping the industry's future. MoldMaking Technology recognizes the industry's young talent through its 30 Under 30 Honors Program.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

-

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

.png;maxWidth=300;quality=90)