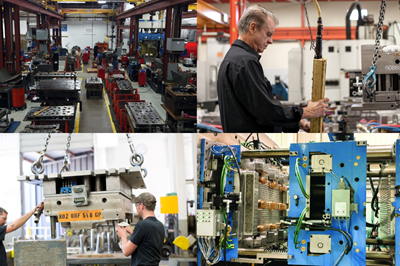

10. Machine Monitoring Platform Improves Machine Utilization, On-Time Delivery

Photo Credit: Westminster Tool Inc.

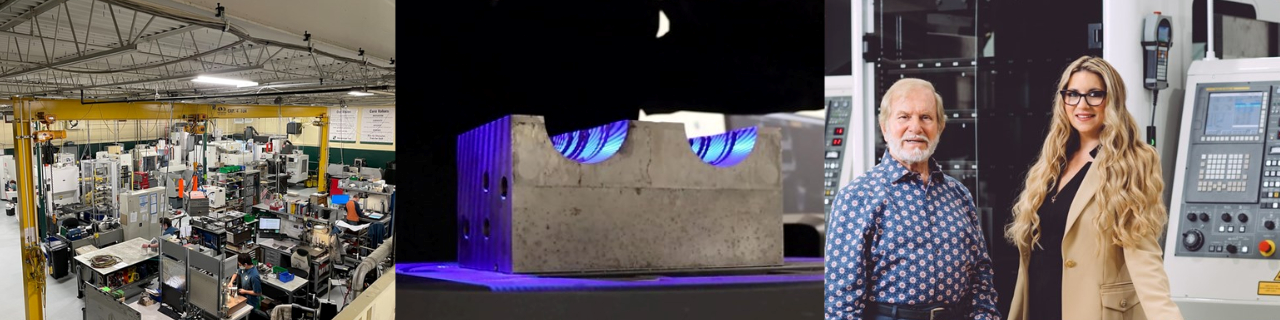

In this case study, we check in with Westminster Tool Inc., a familiar name to MoldMaking Technology readers. Recognized twice as the Leadtime Leader by MMT in 2014 and 2021, the company has seen three of its employees featured in MMT’s esteemed 30 Under 30 list for 2021. Adding to its accolades, company founder and president Ray Coombs received the prestigious Mold Builder of the Year award from the American Mold Builders Assn. (AMBA) in 2021. Operating with a team of 35 individuals and utilizing a spacious 26,000 square feet/2,416 square meters of floor space, Westminster Tool specializes in crafting 20-25 small-to-medium size injection and resin transfer molds annually, focusing on high-complexity, tight-tolerance molds for the medical industry. Their production tools cater to presses ranging between 10 and 350 tons/9.1 and 318 metric tons in clamp tonnage, alongside their expertise in injection molding and custom CNC machining of metal parts. Read the full case study.

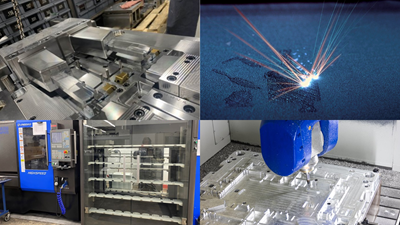

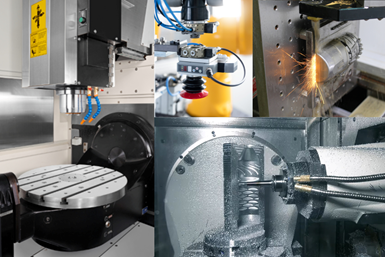

8. Select End Mills With Mold Material, Features and Machining Process in Mind

Selecting the right end mill holds immense significance for mold builders facing diverse milling applications. The choice depends on several factors, including the mold's manufacturing stage, the material being worked on, and the specific features being milled. Whether it's the roughing process involving substantial material removal or refining a pre-roughed part post-heat treatment, the end mill selection varies accordingly. In this guide, we explore challenges and offer valuable tips for effectively navigating milling tool selection across five crucial areas in mold machining. Read the full article.

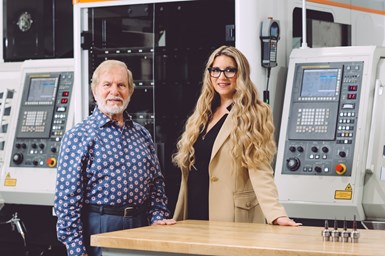

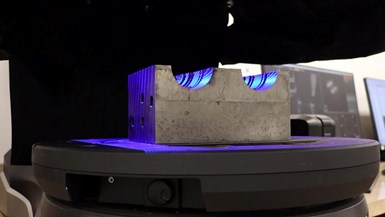

6. MMT Chats: How to Implement a Remote Validation Process

Accede Mold & Tool Co., a family-owned mold builder in Rochester, New York, responded to travel restrictions and customer budget limitations by devising a remote mold validation process. Initially conceived due to pandemic-related challenges, this innovation persists, offering significant time and cost savings for customers while benefiting the mold builder. Vice President of Sales and Marketing, Camille Sackett, shares insights into the company and success of the ACCEDE Remote Mold Validation process. Watch the interview.

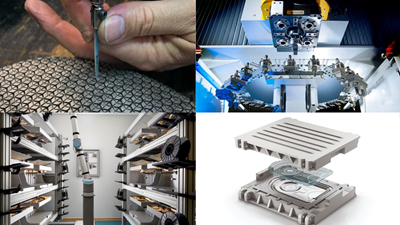

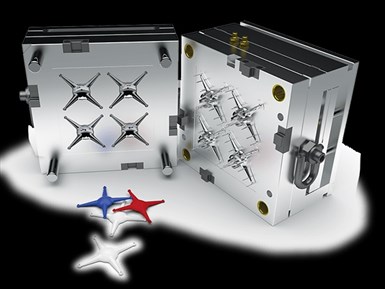

4. Combining Innovation and Artistry to Build Complex, Precision, Multi-Cavity Molds

American Tool and Mold (ATM), situated in Clearwater, Florida, has over 45 years of experience in crafting intricate, multi-cavity molds for the plastic injection molding industry. Founded by Demetre Louourgas, a Greek immigrant turned U.S. citizen, ATM operates with a workforce of 160 across a sizable 150,000-square-foot primary manufacturing facility and an additional 15,000-square-foot hard milling facility on a 10-acre property. Their expertise spans a wide array of molds, from thin-wall and stack molds to hot runner, unscrewing, and high-cavitation two-shot molds, serving industries like consumer packaging, specialty closures, and medical sectors. Read the full profile.

2. 5 Hot Runner Tips for Moldmakers and Molder

Effective collaboration between the mold builder, hot runner supplier, molder, and resin supplier is pivotal in designing and constructing a hot runner mold. However, after the mold's delivery, the responsibility largely shifts to the molder or OEM customer, underscoring the significance of ongoing collaboration during mold validation and production. To aid in the initial startup of a hot runner mold and establish a robust preventive maintenance plan, here are five essential tips offered along with guidelines for effective implementation. Read the full article.

Read Next

MoldMaking Technology's Hottest Tips of 2023

The staff at MoldMaking Technology prides ourselves on bringing you the most helpful, relevant tips in the industry. Here are the top five most-viewed tips of 2023 based on Google Analytics.

Read MoreMoldMaking Technology's Most-Viewed Case Studies of 2023

MoldMaking Technology’s case studies present a shop’s problem, solution and results in thorough detail. Take a look at our top five most-viewed case studies based on Google Analytics.

Read MoreMoldMaking Technology's Most-Viewed Profiles of 2023

MoldMaking Technology's profiles feature insightful interviews and stories about professionals and their experiences in the moldmaking industry. Here are the top five most-viewed profiles of 2023 based on Google Analytics.

Read More

.png;maxWidth=300;quality=90)