March 2024 Technology Roundup Highlights

In this most recent roundup, MMT continues to present the breadth of new or proven technologies that target the moldmaking industry, from cutting tools to software to hot runner products, that have been shared this month.

MoldMaking Technology staff continue to curate a list of relevant technologies in the form of roundups for readers to get a glimpse of what’s new and what’s improved. Tech roundups are a great way to stay informed on innovations hitting the market, or even to discover your next equipment investment to take your shop to the next level.

This month’s roundup features products, processes and services involved with software, hot runners, cutting tools and more. To learn more about the products, read on.

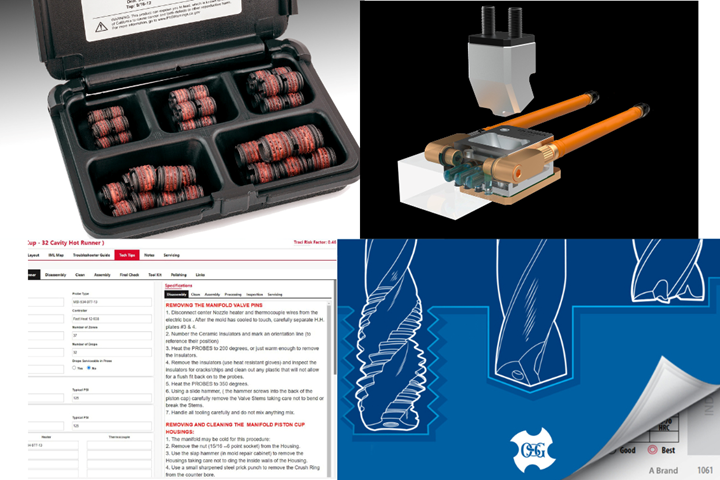

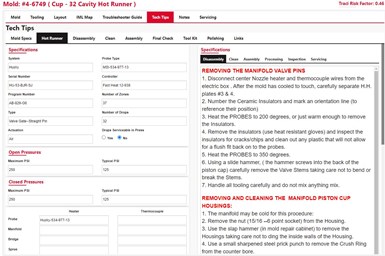

Mold Software Gives Shops a Proactive Approach to Maintenance Tracking

MoldTrax presents MTLinX, the newest version of its popular documentation tracking system MoldTrax contends that MTLinX is the only mold maintenance program created specifically for efficient tracking of the performance, maintenance efficiency and repair costs of injection, rubber, blow and die-cast, stamping, cutting and forming dies. MoldTrax’s distinctive architecture enables the use of a shop’s standard terminology throughout the system instead of typical, confusing journal entries that conventional systems may use.

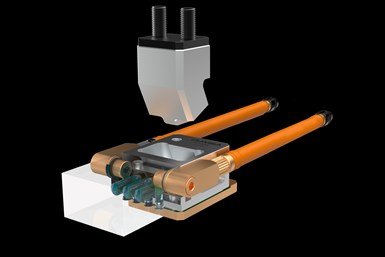

Compact Slides Provide Option for Difficult-to-Cool Locations in Molds

Targeting the challenges behind removing heat during the molding process, CUMSA USA introduces a new feature to its compact slides (part number CS) with a floating insert. The enhanced mold component, the CR cooled compact slide, provides an option to include cooling systems for difficult-to-cool locations, eliminating the need for a high precision pocket.

Hot Runner Accelerates Precise Temperature Control via Enhanced Response

PCS Company’s MCS Hot Runner Control Systems use the latest technology to accelerate temperature control precisely and effortlessly. Featuring fast control behavior and optimized intuitive operation, the system is said to bring controller functions that even untrained users can operate safely and confidently.

VMC Provides Versatile Machining of Complex Parts

Mazak’s VC-Ez 20X vertical machining center (VMC) provides accurate, cost- effective processing of complex parts via 3+2 or full five-axis machining. It features a rotary/tilt trunnion table with roller gear cam technology. For part-size flexibility, axis travels on the VC-Ez 20X measure 31.5" in X, 20.08" in Y and 20.08" in Z (1050 mm × 510 mm × 635 mm), with a rapid traverse rate of 1,260 ipm (42,011.6 mm/m) on all three axes.

Read Next

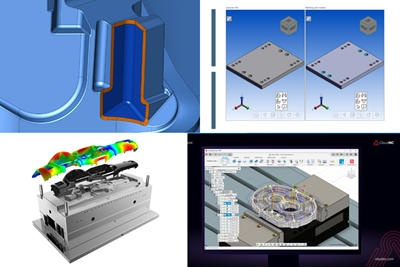

Design, Management Software Resources for Mold, Die Applications

As technology advances, so too do the options available to efficiently design molds or manage the data involved in their progress and production. Here’s a roundup of some of those solutions.

Read MoreRelevant Technologies Serving the Moldmaking Industry

As spring rounds the corner, companies are ramping up their new product/service releases, or highlighting optimized versions, all to reduce lead times, enhance quality and precision and keep projects on track. To learn more, read on.

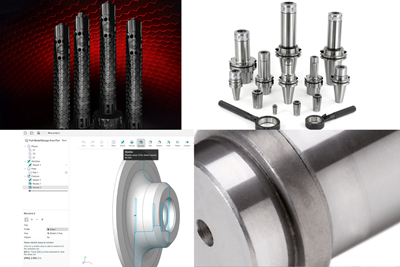

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)