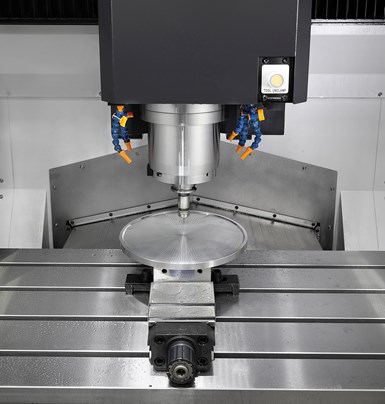

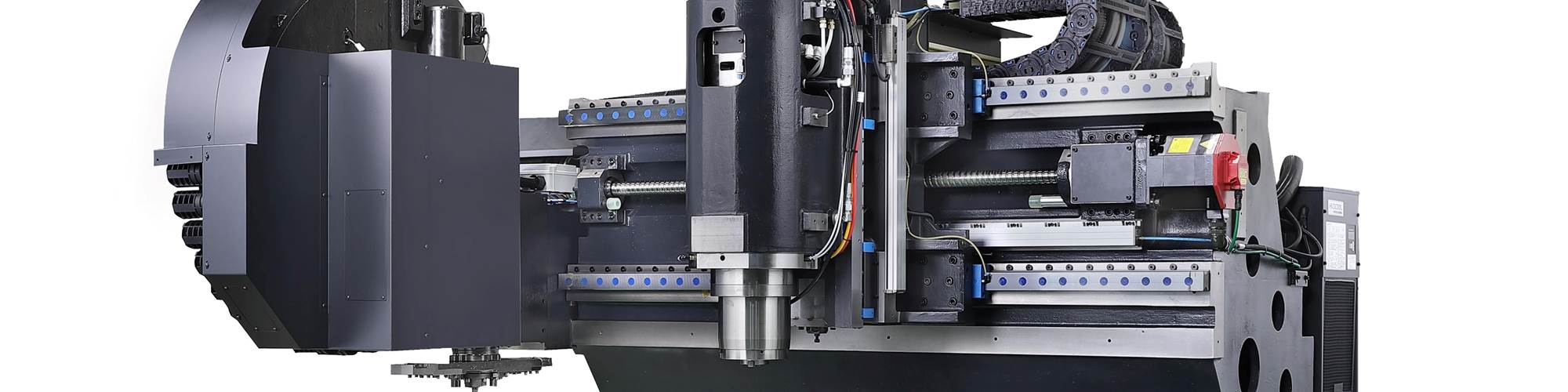

Bridge-type construction improves rigidity and responsiveness, ensuring a smooth surface finish. Photo credit, all images: DN Solutions

Bridge-type construction improves rigidity and responsiveness, ensuring a smooth surface finish. Photo credit, all images: DN SolutionsEveryone likes a bargain, but cutting corners in a precision tolerance application like moldmaking can cost a shop in the long run. For example, there are new machine models that machine tool builders have created off an existing foundation to minimize cost. The builder takes an existing machine and swaps the spindle for higher output if an application requires higher spindle horsepower. While it might work, they are not considering other aspects of the machine that can make the upgrade ineffective.

Similarly, a machine designated as “general purpose” will be a compromise for any given application. Again, there are properties related to size, horsepower and speed that give such a machine the level of versatility to handle a wide range of applications, but is that good enough for moldmaking?

Mold Machining Needs

For a shop manufacturing molds, its machine’s requirements will focus on surface finish range and how quickly they can be turned around, equating to machine rigidity, spindle speed, power and CNC options that help run complex programs smoothly.

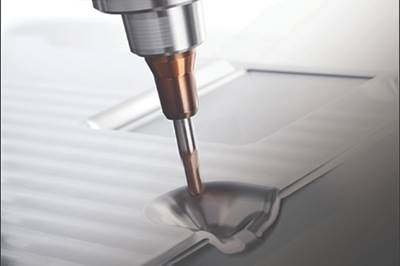

Vibration and heat are enemies when manufacturing molds. If you don’t have a solid machine base with proper dampening and cooling characteristics, you’ll have marks in your mold, and you may even find yourself breaking tools or dealing with thermal growth.

Mold builders should have high-speed, high-precision machining and a rugged, compact package in mind when evaluating machine tools.

Optimal surface finishing also requires stability. Bridge-type machines are superior in this regard. A bridge-type machine’s Y-axis is independent of the other axes and can handle heavier workpieces. The X-axis is carried on a massive bridge structure for better rigidity, and the Z-axis is mounted to that of X. The spindle head also is positioned closer to the supporting Z-axis, minimizing thermal growth and keeping cutting forces closer for better transfer of motion/power.

Extended spindle nose minimizes need for longer tools when machining molds with deep pockets.

A machine designed explicitly for moldmaking should provide strategies for high-speed machining or contouring applications. This is all down to the CNC control and tooling. Faster CNCs that can change and program on the fly for speed or accuracy, plenty of block look-ahead and program space, and easy ways to get large mold programs into the control will give a moldmaker a leg up in mold machining. On machines that don’t have these features, the shop will find that it might not have enough program memory, must run slower due to reduced processing speed or overshoot because of a lack of look-ahead and servo adjusting.

All machines made for mold machining have some features for thermal stability, such as linear scales for direct positional measurement, chillers to remove heat and some compensation mechanism to adjust for any remaining thermal growth. However, the model a mold builder selects should have a complete thermal management package for best results.

Mold Machine Features and Functions

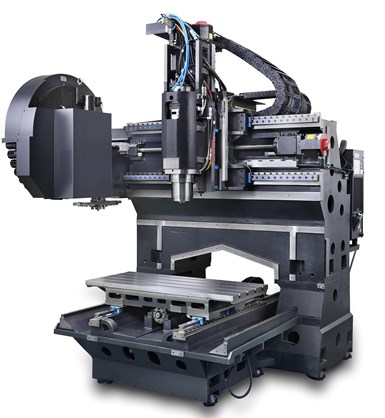

Mold builders should have high-speed, high-precision machining and a rugged, compact package in mind when evaluating machine tools. Consider a bridge-style vertical machining center (VMC) designed to create a moldmaking machine tool from the ground up.

Its bridge frame structure combines a 15,000 rate/minute built-in spindle powered by a 50-horsepower motor that outputs 158 foot-pounds of torque to optimize precision and productivity. This enables high feed rates when machining aluminum or doing heavy cuts in tool or mold steel. The machine is massive, weighing 17,000 pounds.

A machine designed explicitly for moldmaking should provide strategies for high-speed machining or contouring applications.

The bridge-type structure is often found on many higher-end VMCs designed to stay in the cut for extended periods. With minimum stacked axes, compared to a three-axis vertical with fourth/fifth-axis tables and a reduced number of joints, the bridge type is a superior structure compared to the standard C-frame. It delivers more stiffness, along with better accuracy and speed. The bridge frame also enables the spindle carrier to be closer to the axis, bringing better thermal expansion benefits.

Reduced footprint with larger work envelope allows for use in shops with limited floor space.

The proper control is vital to the machine, too. For example, one with a 1-gigawatt capacity high-speed data server that can handle a shop’s program storage needs and a package consisting of AICC II with 200-400 block look-ahead and smooth tolerance control.

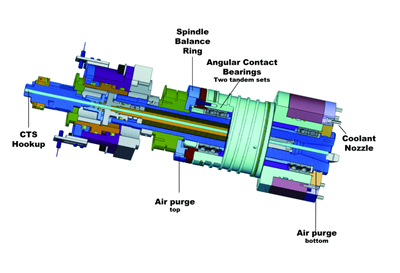

The spindle cooling system circulates refrigerated oil around the spindle, helping to minimize any effects of thermal growth, while a high-pressure air-oil mist system applies lubricant directly to the spindle bearings, extending service life. In addition, hardware sensors monitor the spindle and bed structure temperature and the collected data feeds into a software algorithm, compensating the Z-axis for thermal growth and helping to maintain tight part tolerances.

Maintaining a high surface finish quality is a must for any mold builder. Why take a chance on a “jack of all trades” compromise? Instead, consider machine tools designed and built with the mold builder in mind.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

Horizontal Machining Centers Are Not Just for Big Manufacturing

Horizontal machining centers can help reduce the coolant, perishable cutting tools and labor costs associated with running a machining center in shops of any size.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read More

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)