Inspection and Measurement

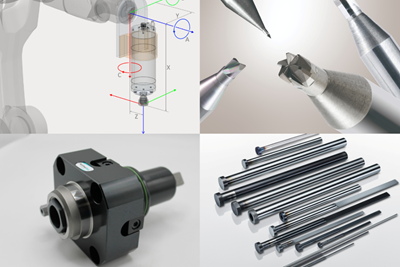

Inspection and measuring equipment includes all of the tools and devices—such as coordinate measurement machines and software, probes, vision systems, balance machines, calibrators and scanners—that are used to verify that a mold and/or part’s dimensions all conform to the tolerances required by the part’s design.

ESSENTIAL READING

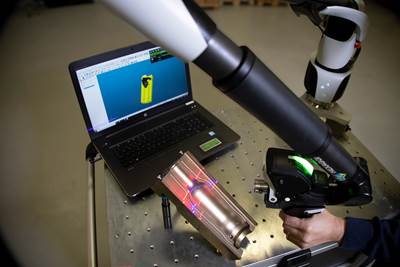

VIEW ALLFour Uses for Tactile Probing and Laser Scanning in Moldmaking

Laser trackers with their probing and scanning capabilities are embedded in almost every stage of the moldmaking process.

Read MoreThree Advances in Vision Measuring Technology for Moldmaking

Next-generation metrology solutions are streamlining shopfloor automation and quality control for mold builders.

Read MoreIntuitive, Easy-to-Use Inspection Software for Portable Probing and Scanning Simplifies Mold Measurement

Enhanced inspection software and hardware with portable measurement, analysis and reporting improves productivity.

Read MoreFive Things a Mold Builder Should Know about Non-Contact Blue Light 3D Scanning

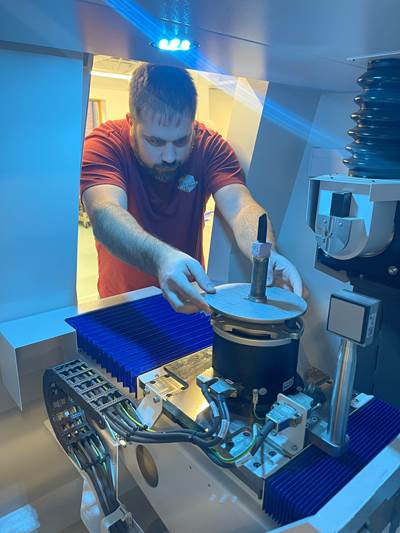

Mold builders who use non-contact blue light 3D scanning reap the benefits of digitization throughout the mold manufacturing process.

Read MoreBreaking Down 3D Scanning in Moldmaking

Identifying 3D scanning requirements and implementing the appropriate technology.

Read MoreStatistical Process Control/Statistical Quality Control Lessons for the Small Mold Builder

A proper statistical process control/statistical quality control system can catch errors early to ensure machining consistency of molds and mold bases.

Read MoreLatest Inspection & Measurement News And Updates

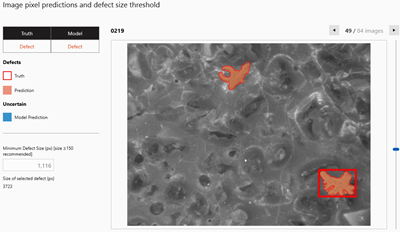

Fully Automated Inspection Sensor for Mold Surface Quality Assurance

Zeiss Abis III combines high-speed inspection with reliable detection of all relevant kinds of defects, ensuring a balance between inspection, speed, robustness, reliability and usability.

Read MoreUsing CT Scanning to Qualify Molds Faster

Software and hardware advances reduce dimensional inspection with part-to-CAD by 70%.

Read MoreQuality Control Technologies Geared for Injection Molds

These latest technology solutions, from noncontact gages to test probes and automated inspection systems, aim to minimize production risks and ensure optimal quality control practices for moldmaking.

Read MoreHandheld Laser Scanning Technology Designed for Ease of Use, Efficiency

Zeiss T-Scan Hawk 2 is a lightweight scanner with hyperscale calibration and satellite mode for metrology-grade precision.

Read MoreElectronic Inspection Gage Provides Compact Handling

The 765A Electronic Snap Gage is designed for machinists, quality control personnel and others who need to quickly measure the size of materials up to 0.5" (12.7 mm) thick.

Read MoreX-Ray CT Systems Meet Diverse Inspection Needs

The next-generation Nikon Metrology VOXLS family includes the large-volume VOXLS 40 C 450 that is available now and four medium-sized models coming later in 2023.

Read MoreFeatured Posts

Technology and Sourcing Guide 2023: Inspection/Measurement

Inspection and measurement equipment includes all of the tools and devices used to verify that mold and part dimensions conform to the tolerances required by the part’s design

Read MoreVIDEO: Maintaining a Customer-Centric Culture

Progressive Components President Glenn Starkey talks about the importance of the customer and culture when developing technology solutions for the moldmaking industry.

WatchThree 3D Scanner Investment Considerations

Mold builders taking advantage of laser and software advancements for portable 3D measurement tools can reduce inspection and measurement times.

Read MoreTechnology Roundup: New/Improved Technologies You Don't Want to Miss

With all the technology joining the market, moldmaking is a versatile, ever-evolving industry. As such, this technology roundup has no specific theme — it features a variety of products for applications and solutions across the industry.

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreCT Scanning Helps Micro Molder Reduce Cost of First Article Inspections

CT scanning services performed by 3D ProScan, a division of NyproMold Inc. provides MTD Micro Molding with accurate, high-resolution internal and external measurements performed about seven times faster and at significant cost savings.

Read MoreFAQ: Inspection & Measurement

How can moldmakers digitize a part for inspection?

The first step of digitization in molding is 3D scanning the part. 3D data can be easily captured on site, and users benefit from swift run times, low cost, efficient handling and easy communication. The second step is processing the 3D scan data into CAD data by converting the point cloud generated in the 3D scan into CAD/CAM-capable data. The processing of the STL data produced by the 3D scanner is then reconstructed in CAD.

The part’s characteristics can be recognized based on the scan points, and these points can be replaced with CAD-capable surfaces. This process is called surface reconstruction. With the finished data of the CAD/CAM solid model, the mold build can start.

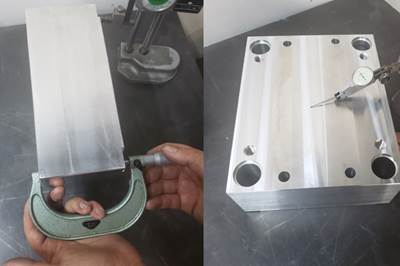

Traditional mold measuring methods are generally done manually using contact measuring tools such as vernier measuring tools or micrometers. A few attributes, such as mold width, height and depth, can be measured, while the surfaces’ curvature and concave surfaces are challenging to measure. These measuring methods can be complicated and time-consuming and make it challenging to ensure large mold measurements’ quality and accuracy.

So, noncontact 3D scanner measurement is gradually becoming one of the primary mold inspection and measurement methods. There is a wide array of 3D inspection tools powered by different scanning technologies. For example, blue light 3D scanning. This process precisely captures small and filigree details of small- to medium-sized objects rigidly requiring persistent performance in their product lifecycle.

How can automation improve overall shop floor measurement?

Shop floor inspection can be a tedious or relatively innocuous part of daily operations, depending on the measurement and analysis methods shops use. However, automated measurement equipment solutions, comprising a CNC coordinate measuring machine (CMM), flexible part fixturing, and automated part handling systems, enable operators to quickly and easily change the configuration in hours versus days to accommodate completely different or redesigned parts on the shop floor during production.

The automation also eliminates the need for dedicated measurement equipment for each mold, mold component, or even molded part, while simultaneously streamlining the analysis and storage of measurement data into smart systems. A smart system combines computer-integrated manufacturing, high levels of adaptability, rapid design changes and digital information technology to achieve a system that monitors the entire process.

For example:

- Equipment status

- Working time

- Idle time

- Maintenance

- Process stopped, the attention required

- Equipment condition

- Preventative maintenance

- Potential component failure predictability

- Measurement data management

- Monitoring for compliance with manufacturing design

- Process control for constant adjustment feedback

- Historical data archiving

Source: Improve Overall Inspection with Automated Measurement

What should moldmakers consider when choosing a measurement system?

Cost and value are important considerations when determining the value of one measurement solution over another for a particular application. However, a more essential consideration is the type of part or mold that needs to be measured and measurement turnaround time. For example, a company is building molds for a component that is the size of a soda bottle. For quality inspection, what is the fastest approach? What is currently being used to inspect molds, such as hand gages or traditional CMMs for tactile measurements?

Further considerations include the measurement task at hand. Is it a mold’s surface geometry or points or features? How can this data be moved toward process inspection? Does the application require 100-percent surface coverage that can be captured using a 3D optical scanner with a larger field of view? Does the operator need to verify a small, concentrated area of a mold, which is an ideal application for a flexible and portable measuring arm? Are accurate baseline scans of molds needed, or is it a reverse engineering job? Once these needs are clarified, a moldmaker can better determine the appropriate technology to address its multi-faceted measurement and inspection requirements.

No matter what the solution is, the metrology options today are light years ahead of yesterday’s tools, with easier-to-use software and hardware interfaces. But there is more to the story than that. 3D data-driven processes integrated throughout the product development cycle are the wave of things to come in the smart factory, and that includes metrology. Inside the smart factory, systems will continuously collect and process data during production operations, providing speed and confidence for fast decision-making and rapid responses to shopfloor issues. Moldmakers who embrace a digital thread will make their operations more flexible and adaptable for a new level of quality control.

Source: Data-Driven Quality Control

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)