Data Management Software and Enterprise Resource Planning

ERP stands for “Enterprise Resource Planning.” Some of the functions associated with ERP and related management software include: Costing or estimating the time and cost of production, scheduling a job for production, and in-process job tracking, or logging each step in a part’s progress through the shop, so a part’s current status can be immediately known. ERP systems also provide a historical view of resources required on prior jobs which can be very helpful in planning new work.

ESSENTIAL READING

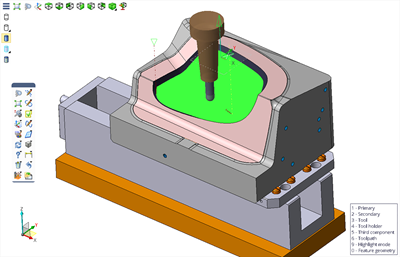

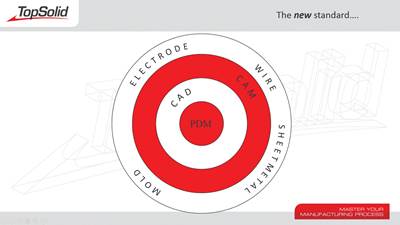

VIEW ALLHow to Customize an Interoperable Software Solution for Your Moldmaking Process

A connected software solution streamlines the moldmaking process by providing a unified source of design data, enhancing efficiency and reducing errors, with five key steps benefiting from this integration.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

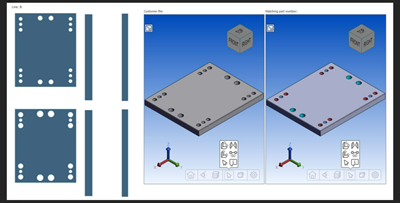

Read MoreHow to Use Automation to Minimize Mistakes and Speed Mold Build Process

A guide to capturing and reusing company knowledge and experience with software automation.

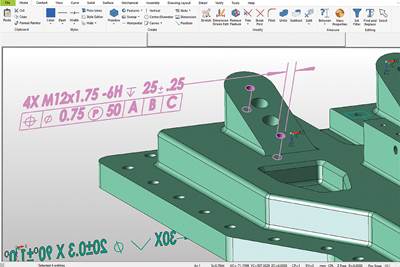

Read MoreThe Role of Model-Based Definition in Precise Mold Design

Model-based definition replaces technical drawings to communicate precise product definitions between designers and manufacturers.

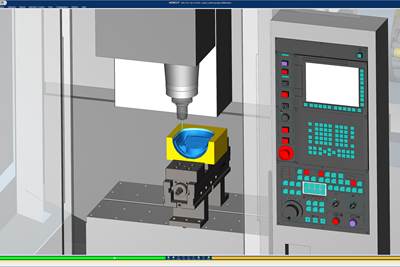

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreLatest Data Management Software News And Updates

Visual Search Application Instantly Locates Data Needs

VizSeek visual search technology enables users to avoid spending hours hunting through databases to locate drawings, or duplicate already-existing work when quoting or manufacturing injection molds.

WatchDesign, Management Software Resources for Mold, Die Applications

As technology advances, so too do the options available to efficiently design molds or manage the data involved in their progress and production. Here’s a roundup of some of those solutions.

Read MoreNew Year, New Popular Articles from MoldMaking Technology

The top ten most-viewed articles in January reflected not only what our readers wanted to see—but also what is new and trending in moldmaking.

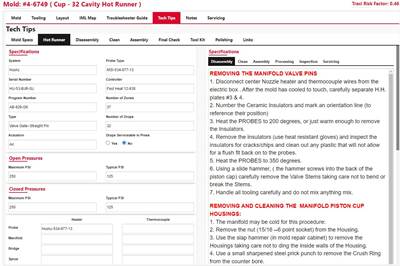

Read MoreMold Software Gives Shops a Proactive Approach to Maintenance Tracking

MoldTrax releases feature updates to its MTLinX documentation tracking system to ensure your shop’s molds are running as efficiently and reliably as possible.

Read MoreManaging all That Data

Product data management may have a bad rap, but making it a priority rather than an afterthought can help make the most of your design and machining information.

WatchHow to Use and Protect Remote Machine Monitoring Data

Collecting, analyzing and securing machine data in real time can substantially improve productivity, profitability and customer satisfaction.

Read MoreFeatured Posts

MMT Chats: The Science of Moldmaking, Part 2

In Part 2 of this two-part MMT Chat, Christina and Don continue their conversation by exploring lean manufacturing and tips on how to attract, train and retain the future workforce.

WatchMMT Chats: The Science of Moldmaking, Part 1

MoldMaking Technology Editorial Director Christina Fuges chats with Don Smith, North American Senior Tooling Engineer for Scholle IPN in Northlake, Illinois about the future and science of moldmaking.

WatchMachine Monitoring Platform Improves Machine Utilization, On-Time Delivery

Using data from a machine monitoring platform, Westminster Tool added almost 75 hours of capacity per week by shortening warmups and starting CNC and EDM machines sooner.

Read More5 Steps to Get Started With Digitalization

Knowledge, a strong partner, an internal champion and an active regular participation in highly visible data will help smaller mold shops with digitalization.

Read MoreDo You Remember?...The Best of MMT September

Say, do you remember? These top-viewed MMT articles from September?

WatchHow to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)