Manage

Organizing Your Shop Through Communication

Visual communication is a key factor when choosing an organizational tool.

Read MoreHow to Achieve Economical Five-Axis Milling

Although moldmaking has not had great incentives to invest in five-axis technology like the aerospace industry, there are still many reasons for moldmakers to adopt five-axis machining, and there are a few interesting software functions that help to make five-axis programming economical.

Read MoreGuidelines to Put Your Production Process on the Profitability Track

A top-down commitment to investigate new options for molding materials, release agents, training techniques and equipment is critical to reduce mold downtime.

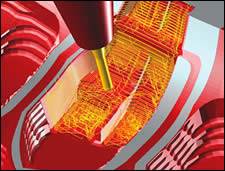

Read MoreThe Moldmaker’s Role in Controlling the Molding Process

How the toolmaker/mold designer can make the best choices when it comes to in-mold cavity sensing and control; how to do a good installation; basic functionality of the sensors; and, post installation care.

Read MoreHow to Solve Common Inventory Management Problems Related to Tooling

A practical look at what to consider when purchasing client/server inventory management software and how to implement such a program, as well as why and how it can benefit mold manufacturing operations.

Read MoreLooking Back

It’s that time of year again, when we tend to look back at the past 12 months and all that they have brought us, and then look ahead to the New Year and what is to come.

Read MoreHow to Increase Polishing Efficiencies

A concurrent approach to polishing increases the man-and-machine efficiency while streamlining workflow to help attain ever-decreasing leadtimes.

Read MoreAnalyze Your Data

Ways to collect and analyze data and get employees involved in the process.

Read More