Organizing Your Shop Through Communication

Visual communication is a key factor when choosing an organizational tool.

In a manufacturing environment strength is achieved through communications. Because technology contains so much promise, we tend to think it will solve all of our problems, but shop management needs to look at visual communication tools when trying to improve communication with workers on the floor, as well as organize the shop and scheduling shifts.

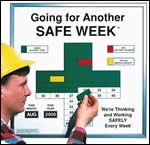

Safety is clearly a goal in any facility. For example, a plant manager who was frustrated with his workers’ safety record and preached the need for safety, could not get it to sink in at the plant. It was decided that if workers could be shown their safety track record in one glance, it would be not only a goal, but an educational and motivational tool.

A solution is a safety awareness motivational system that consists of a framed, porcelain-like magnetic steel white board; heat-fused printed with a cross design divided into segments of 52 weeks, 31 days, 12 months or 365 days, and space for this month, year and legend; plus green, red and yellow die-cut magnets to fit the segmented cross time and legend segments; and a magnetic 12-month and 10-year set.

The blank cross represents a new year. Each safe accident-free week (day or month) is represented by a green magnet. A week in which an accident is reported is marked by a yellow or red magnet. At the end of the year, 52 magnets fill out the cross. The number of yellow and red marks instantly stands out—demonstrating a department or plant’s overall safety record for the year. Many departments display up to a 10-year safety history. Nobody wants to be associated with the yellow or red magnet, particularly when it has a 520-week display life.

Visual communications in a manufacturing setting can make a big difference. But despite the importance of safety, other day-to-day information such as production metrics, quality issues, kanban card display, job specifications, work prioritizing, task assignment, schedules, memos, photos and important announcements need to be seen and continually viewable through the workday, by both workers and management.

But placing that information in a useful (i.e., highly visible) place, particularly when the nearest wall can be 100 yards away, is a challenge.

Some methods for better communication with employees include large boards on rolling stands to post critical information, but the size of these boards block critical lines of sight and could only be viewed from one side.

A better tool is a rotating bulletin kiosk tower. It’s a four-sided board that takes only 19 x 19 inches of floor space but contains 24 square feet of display surface (equal to a 4' x 6' board) and turns silently with the touch of a finger. Managers place information exactly where the people are; in the work stations and along heavily trafficked areas. Workers, visitors and management can see it from all sides.

These solutions come from recognizing the strongest tool that any worker can have—visual communication. It’s effective, works around the clock, can be viewed as long and as often as necessary without programming skills and is essential to keep a shop running efficiently, profitably and safely.

Related Content

Indiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreTen Things Mold Builders Should NOT Do

What you don’t do can be just as important as what you do, sometimes even more so. One thing great mold builders do is take note of what gets in the way of their success and stop doing it.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreHow to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreRead Next

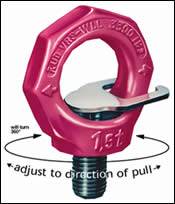

Proper Use of Lifting Points

A look at unsafe lifting shortcuts that can lead to injuries in your shop and some possible solutions.

Read MoreThe Key to Fire Protection in Your Shop

Five considerations for EDM fire suppression system selection.

Read More

.jpg;maxWidth=300;quality=90)