Manage

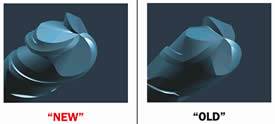

Minimal Investment In New Tooling Tech Increases Productivity, Tool Life and the Bottom Line

Having a fundamental base of the facts makes it easier to detail how some of the latest innovations in cutting tool substrates, geometries and coatings can make it easier for one’s moldmaking process to go from fast to furious.

Read MoreSupply Chain Best Practices

Shops must do their part to prevent the production and sale of counterfeit products, and one aspect in their control is the security of their supply chain.

Read MoreWhite-Light Scanning Validates Faster, Better Processes for Molded Auto Interior Trim at Eifel Inc.

The use of white-light scanning and photogrammetry ensures accuracy of tool building programs.

Read MoreTech Tool & Mold, Inc.: Strength and Flexibility

This moldmaker garners the 2007 Leadtime Leader Award: Small Shop by being flexible with its customers, going lean, competing globally and uniting with other moldmakers.

Read MoreYour Industry, Your Show, Your Future

On April 18th and 19th the MoldMaking Expo—presented by MoldMaking Technology magazine—will return to Rosemont, IL, for its ninth year.

Read MoreDon’t Build the “Same Old Same Mold”

Steps for evaluating the latest mold innovations in order to move along the evolution process.

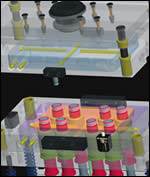

Read MoreSpray Form Technology Fills the Gap in Plastic Mold Tooling

New method for producing steel yields significantly better overall tooling economy.

Read MoreDo-Rite Die & Engineering: Doing Right by Its Customers With Die Cast Dies

Learning the intricacies of die cast die building offers moldmakers an alternative to mold manufacturing and can generate more repeat business.

Read MoreLearning Outside the Shop

What better way to learn outside the shop than to attend some trade shows.

Read More