Machining

Single-Source Machine Tool Solutions Associated with Mold and Die Machining

YCM Technology USA highlights its latest lineup of application-based machine tools at IMTS 2022, available as part of the YCM Alliance, a customer-centric program bringing together application-based system supplies.

Read MoreCylindrical Grinder Shows Off High Precision

The United Grinding Studer S131r cylindrical ID-radius grinding machine targets tough ID grinding operations and a range of hard-to-machine materials. See the machine at IMTS 2022.

WatchCNC Mill/Drill/Tap Centers Feature High-Speed, High-Torque and High-Volume Machining

Absolute Machine Tools’ Seiki KT Series, to be showcased at IMTS 2022, is now offered in six models with three spindle configurations, including for mold detail machining applications.

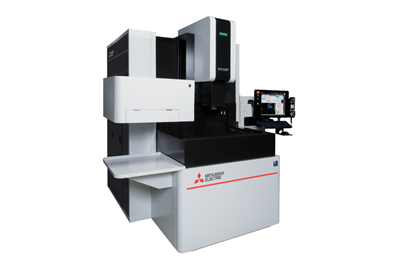

Read MoreEDM, Precision Milling Technologies Highlight High-Precision Features for the Moldmaking Industry

MC Machinery Systems features a range of wire and sinker EDMs, machining centers and automation at IMTS 2022.

Read MoreMachining and EDM Innovations to Look for at IMTS

MoldMaking Technology previews some of the EDM and machining products and exhibitors applicable to mold builders that will be featured at IMTS 2022.

Read MoreVIDEO: Can You Integrate a Joystick onto a Robot for Mold Repair?

Tony Demakis, President of Alliance Specialties and Laser Sales and Brian Conner, Channel Development Manager at Universal Robots answer the question of whether or not you can integrate a joystick onto a robot for mold repair.

WatchMold Builder Gains Higher Accuracy, Repeatability, Productivity from Milling Machine

Very high stability, precision, thermal and vibrational control, and low cost of ownership led Diamond Tool & Engineering to purchase a high-precision, high-speed three-axis milling center.

Read MoreVIDEO: The Capabilities of Micro Molding

In this demo, Sodick IMM by Plustech shares its micro molding capabilities with Matrix Tool and M.R. Mold.

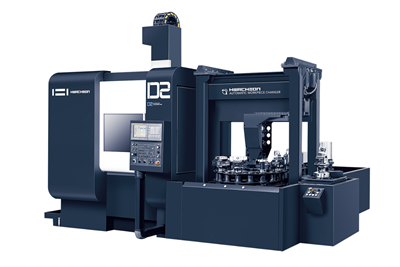

WatchHeavy-Duty, Precise Five-Axis Machining Manages Multiple Projects, Fixtures in One Setup

Typically seen in mold and die, aerospace and general machining applications, Hwacheon’s D2-5AX offers enhanced strength, rigidity and additional features for highly productive machining.

Read MoreCompact Milling Machine Built to Reduce Cutting Time

Hurco releases the VM15Di, built to reduce cutting times and heat transfer while producing improved surface finishes.

Read More.png;maxWidth=728;quality=90)

-02.jpg;maxWidth=300;quality=90)