Machining

Five-Axis Volumetric Compensation Updates Eases Adoption Pain Points when Mold Machining

A new development, the GSC Advanced, offered with Grob’s five-axis universal systems for mold machining, ensures that compensation calibrations can be run even while the workpiece is in the machine.

Read MoreHigh-Speed, Five-Axis Mold Machining Achieved via Extended Barrel Series

Air Turbine Tool spindles can machine at 50,000 rpm in high-speed steel (HSS), accelerating mold machining capabilities.

Read MoreForm Grinder's Advanced Design is Ideal for Mold Base Prep, Inserts

The Okamoto full-function, two-axis, simultaneous CNC form grinder is ideal for surface, slot, step, form and contour grinding, with improved column design and construction, and consistent accuracy.

Read MoreHigh-Frequency Milling Suits Compact Gantry Milling Machine to Moldmaking Tasks

German-made Endura 700Linear series from Fooke is capable of various machining workpiece tasks, including composite, aluminum, cast iron and steel for mold and die-making.

Read MoreHybrid 3D Printer Offers Five-Axis Simultaneous Machining for Mold and Die Applications

DMG MORI’s Lasertec 3000 DED hybrid 3D printer offers process integration by combining laser deposition welding with five-axis, turn-mill machining in one setup.

Read MoreFree-Form, Mold and Die Machining Cycle Times Cut With Multitasking Machine

It is said the machine combines the abilities of a high-powered turning center with a full-function machining center to produce small- and medium-sized workpieces in single setups.

Read MoreCylindrical Grinding System Extends Into Mold and Die Machining

United Grinding’s Studer brand unveils the S36 concept, featuring precise, reproducible cooling capabilities and a large grinding wheel for enhanced punch and die speeds.

Read MoreMidgard Inc. Tackles Tooling Challenges and Automates Production to Keep Molds Running

This Eastern Pennsylvania molder does cavity changes daily, making its in-house toolroom critical to quickly fixing mold problems.

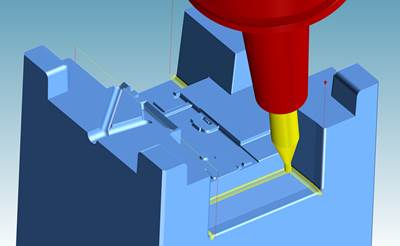

Read MoreModular, Flexible CAM Speeds Five-Axis Programming, Boosts Profitability for Moldmaker

P and C Tool improves mold quality, minimizes secondary processes, takes on new business opportunities and increases profitability with new integrated CAM software.

Read MoreSmall, Agile Mold Builder Keeps Speed and Accuracy at the Forefront

Michigan-based Zero Tolerance tests the limits of moldmaking and molding with teamwork and technology that permits changes on the fly.

Read More.png;maxWidth=728;quality=90)

-02.jpg;maxWidth=300;quality=90)