Machining

Gosiger Named Exclusive U. S. Distributor for Jingdiao High-Speed and Graphite Machining Centers

Availability of three- and five-axis high-precision machining centers focused on small, complex components for the die and mold industry are now supported by eight nationwide facilities.

Read MoreMMT Chats: Twice the Efficiency with Canon Virginia Inc.'s Shuttle Mold System. Also, What Does Customer Outreach Look Like During a Pandemic?

Many people know Canon for their state-of-the-art cameras and equipment. Little do they know, they also have hands in the moldmaking industry. In this MMT Chat, MoldMaking Technology Editorial Director Christina Fuges had the chance to discuss Canon Virginia Inc.'s Shuttle Mold System with Director of Business Development Wayne Daniel. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

WatchMoldmaking Applications Supported by CNC Controller With Fully Integrated Process Monitoring

At IMTS, Heidenhain says it is entering a new chapter in North American shop-floor-centered manufacturing with the TNC7 CNC controller for fully integrated process monitoring and greater functionality.

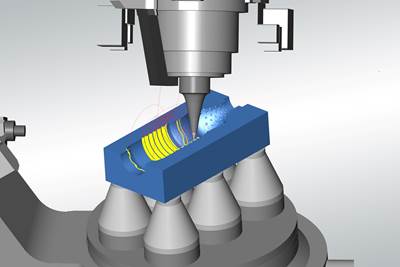

WatchFive-Axis Machining Center With Integrated CAM Software Overcomes Skills Gap

At IMTS 2022, Jingdiao North America is presenting the GRA200 five-axis high-precision machining center which can program parts and measure them on the machine using its proprietary Surfmill CAM software.

Read MoreThree-Axis Milling, Jig Grinding Machine Precisely Machines Large Molds

Roeders’ RXU 2000 is suited for 3D milling, jig grinding, vertical grinding or profile grinding for moldmaking applications such as large mold plates and large, flat injection molds with fine contours.

Read MoreHigh-Precision Grinders Capture Optimal Mold Surface Finishes

Okamoto Corp. highlights the ACC-SA1 series and ACC-32·80CHiQ grinding machines at IMTS 2022 for moldmakers, featuring a degree of precision, flatness and a smooth surface finish.

Read MoreCustomized CAM Strategies Improve Five-Axis Blow Mold Machining

The proper machining process and workflow can impact blow mold production, making your CAM software selection critical.

Read MoreAffordable, Versatile, In-House Regrinding Operations Aimed for Mold Shops

In a floor space of less than 24.8 square feet, Walter’s Helitronic G 200 offers grinding and re-sharpening of rotationally symmetrical cutting tools ranging from 1 to 125 mm (0.039" to 4.92") in diameter.

Read MoreCutter Considerations for Hybrid Additive Manufacturing

Four tips for applying the right cutting tools in hybrid additive manufacturing.

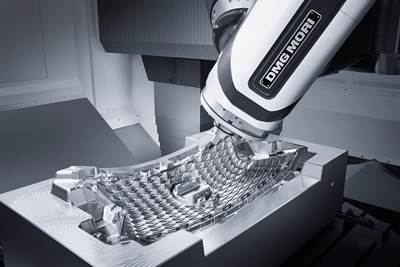

Read MoreExcellence Center Enables Innovation Manufacture of Molds, Dies

The DMG MORI Die & Mold Excellence Center highlights its DMU 210 P machine maximized to produce highly demanding molds and dies with quality and precision.

Watch-02.jpg;maxWidth=728;quality=90)

-02.jpg;maxWidth=300;quality=90)