Heavy-Duty, Precise Five-Axis Machining Manages Multiple Projects, Fixtures in One Setup

Typically seen in mold and die, aerospace and general machining applications, Hwacheon’s D2-5AX offers enhanced strength, rigidity and additional features for highly productive machining.

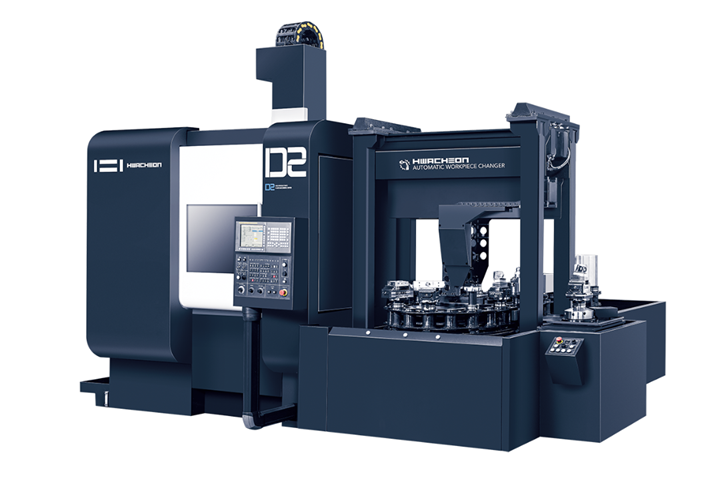

At IMTS 2022 Hwacheon Machinery America showcases the D2-5AX, designed for heavy-duty, precise five-axis machining typically seen in mold and die, aerospace and general machining applications. New to this product is enhanced machine strength, a rigid structure and automation options with an automatic workpiece changer. It is also equipped with Hwacheon’s own software package, including a scheduling system, so that production teams can manage multiple projects, increasing productivity.

With a machine weight of 10 tons, the D2-5AX is said to ensure minimal vibration and thermal growth stability in production environments. For high accuracy and precision, Hwacheon says the D2 5AX is built with the highest quality components which achieve AC/DC values of 0.7 G. The D2-5AX has a range of spindle options beginning with its standard 50 hp high-torque spindle of 12,000 rpm (up to 24,000 rpm). Moreover, temperature sensors on the spindle and the machine bed measure and compensate for thermal factors.

The trunnion-style machining center is also said to be equipped with a 600-mm-diameter round table, providing an ergonomic working height of 950 mm. Up to five axes can be controlled simultaneously with adaptive feed rate control, overload control in the event of tool breakage and collision, as well as compensation for axis misalignment by means of a calibration sphere and measuring probe.

For production operations, the D2-5AX may also be customized with Hwacheon’s automatic workpiece changer, which has the ability to run multiple projects and fixtures in a single setup, a key benefit for mold builders, the company points out. Suitable for complex processes and mass production, the automatic workpiece changer is available as an eight- or 20-pallet option. The work setup station on the automatic workpiece changer is also separately configured from the machine operating area, to ensure users can safely work even while the machine is in motion.

Related Content

-

Developments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

_300x250 1.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)