UL AMCC Visit

After my story with UL AMCC on often-overlooked safety concerns, I was in the area and able to stop by for a quick tour.

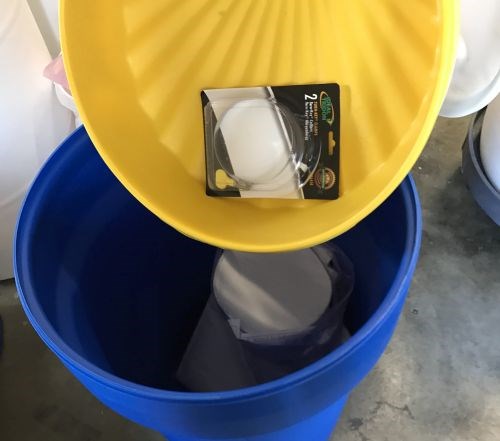

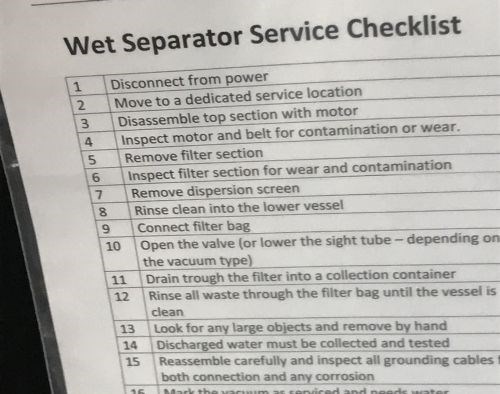

Director of Educational Programming Ed Tackett and GM Paul Bates of UL AMCC welcomed me into the center to show me around the training facility and talk a little shop. David Virgin of Kinetic Filtration also stopped by, so I was able to get an update on his unit that connects to the wet separator and sequesters the metal powders from the waste stream.

On a related note, Paul will be presenting Foundations of AM for Toolmaking and Injection Molding

Tuesday, June 13th 1pm-5pm at Amerimold in Rosemont, Illinois. Topics will include an additive manufacturing industry and technology overview, the four phases of the 3D printing process and activity-based learning on how the technology is being utilized in tool making and injection molding.

Related Content

-

Mold Racks Offer Safe, Practical Access and Storage Solutions

PCS Company’s Mold Storage Racks enable shop personnel to work safely and efficiently, while also providing support and protection for molds, dies and other equipment.

-

VIDEO: Insights and Best Practices for Mold Care

Slide Products President Michael Muth shares the products and practices he believes have helped the moldmaking industry the most when it comes to caring for molds.

-

Mold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)