New Steel Headquarters Facilitate Faster Lead Times

National Tool & Manufacturing Co. relocated its steel headquarters to East Dundee, Illinois. The company says the move facilitates a number of benefits.

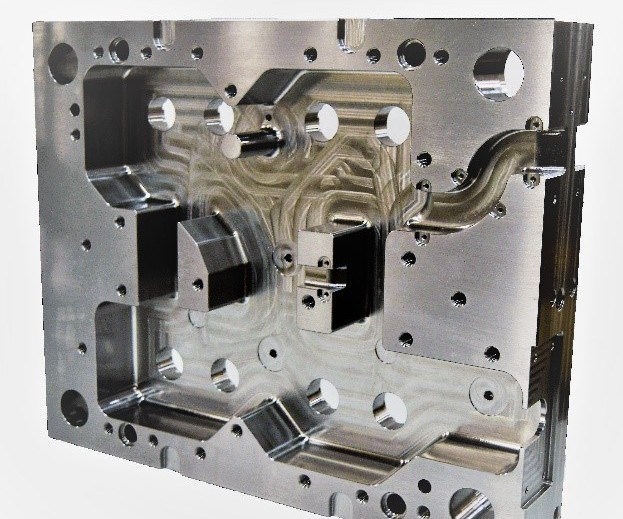

National Tool & Manufacturing Co. (NTM) has expanded operations to respond to customers "quick-to-market" strategies. NTM relocated its steel headquarters to East Dundee, Illinois, in 2018. The company says that the East Dundee location is designed for ideal material handling, storage and production flow as well as for expanded lifting capabilities. NTM says that the move further improves NTM's lead times on processed mold base plates and improves sawing, milling and grinding on both raw and processed mold plates.

The East Dundee steel facility upgrades follow the 2016 expansion of NTM's temperature controlled mold base manufacturing plant. According to NTM, the dedicated machining facility with internal precision grinding capabilities enable premium, "insert-ready" mold-base construction. NTM says that the combined steel service center and mold base manufacturing operation offer a "one-stop" supplier for every size mold builder.

Related Content

-

Self-Venting Mold Steel for Defect Prevention

High-tonnage pressed and sintered, porous metal Vortex removes the difficulties of trapped gas in the mold cavity through a system of interconnected pores.

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection, there are many variables that can dictate the best option for moldmaking.

-

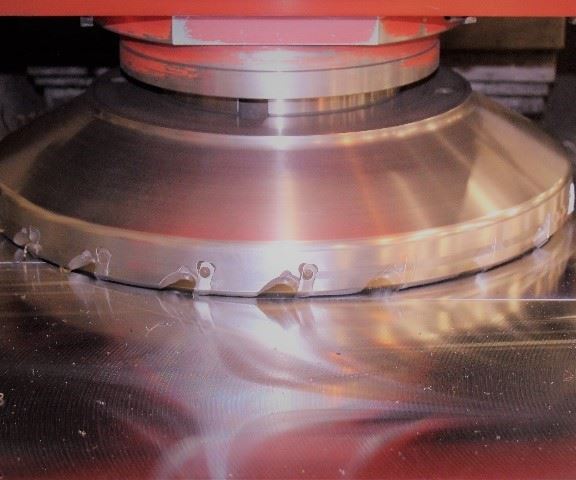

How to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)