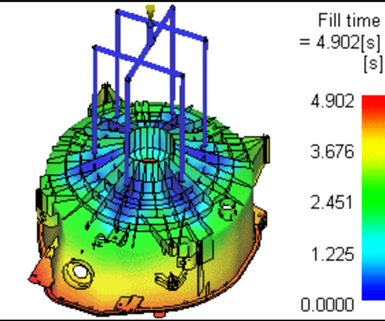

Moldflow Analysis Solves Part Design Concerns

CAE Services uses Moldflow to analyze, identify and solve part design or warpage related concerns before cutting steel.

CAE Services uses Moldflow to analyze, identify and solve part design or warpage related concerns before cutting steel. The company’s staff can evaluate all aspects of the part and mold design from gate size/locations, SVG timing sequences, identifying weld line locations, optimizing cycle times and applying windage to reduce warpage. The company is GM-certified and has the largest Moldflow expert certified team in North America, having analyzed thousands of projects from appliance to automotive to medical. As an Autodesk Moldflow channel partner, CAE Services offers a single point of contact for “Everything Moldflow”, including consulting, software implementation and training.

Related Content

-

Moldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

-

VIDEO: Explaining MoldMaking Versus Mold Manufacturing

To understand how training has been impacted we first need to understand the differences between a few key concepts. What is moldmaking vs. mold manufacturing? Who is a mold designer vs. a mold engineer?

-

Precision Custom Core Pins

Smith Enterprises highlights its wide range of custom core pins for high-cavitation molds.

.png;maxWidth=300;quality=90)