Mold and Plate Supports Enhance Shop Floor Safety

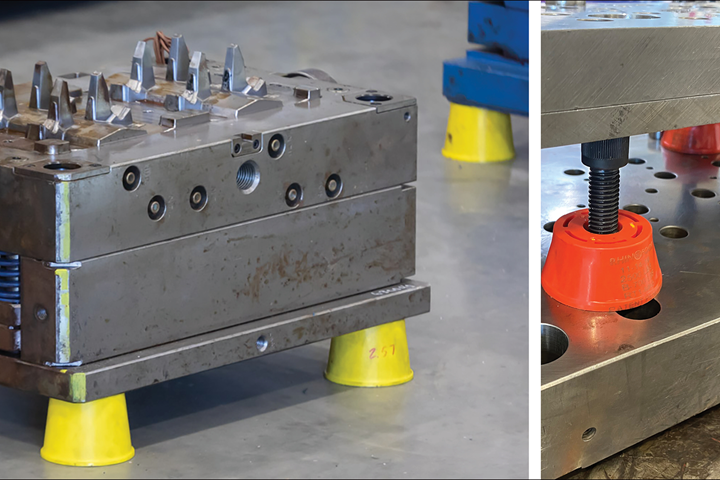

Progressive Components offers RhinoFeet and RhinoToes, support pads that eliminate trip hazards, elevate molds and hot runner systems and can be easily stored.

Photo Credit: Progressive Components

From molds on the floor to tools on the bench, Progressive Components’ new RhinoFeet are said to be a simple, safe and efficient solution for elevating and storing heavy items within the shop. This makes for a safer, cleaner approach when used under molds, eliminates the trip hazard of wood and skids strewn about the plant and improves 5S standards within the shop.

RhinoToes are new to the product range, helping to correctly position plates to avoid pinch points during assembly on the bench. Stabilize plates either with a ½-13 bolt or mount one rhino foot to each end of a threaded rod to support KO plates, stripper plates or hot halves.

The patent-pending RhinoFeet and RhinoToes support pads feature a magnetic insert that is molded directly into the product to enable the pads to travel with the item it is supporting. When not in use, they can be conveniently stored within reach on any metal surface such as I-beams, toolboxes, machines, benches, etc. RhinoToes can be used to support mold plates and hot runner systems when on the bench.

RhinoFeet are now available in 2”, 3” and 4” sizes, with a safe working load of 7,000 lbs., and etched for easy identification from a distance. RhinoToes are offered in 1”, 2” and 3” sizes, with a safe working load of 2,500-3,000 lbs.

Related Content

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

How to Maintain Heaters, Thermocouples, Valve Gates and Controls

An examination of real-world problems and solutions involving hot runner system maintenance.

-

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

_300x250 1.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)