Insert Geometries Expansion Provides More Cost-Efficient Steel Turning Solutions

The ISO-EcoTurn turning insert line has an additional 63 inserts in new geometries with increased nose radii and chipbreaker-style options.

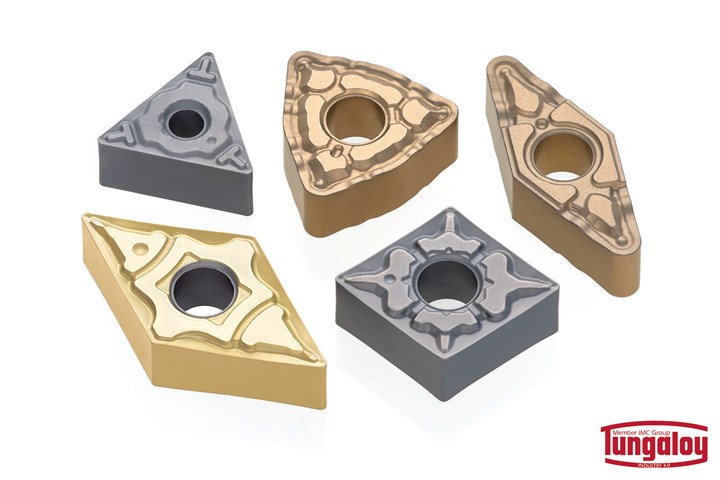

Photo Credit: Tungaloy America

Tungaloy America has expanded its ISO-EcoTurn turning insert line by adding 63 inserts in new geometries.

ISO-EcoTurn inserts, while downsized for tool economy, incorporate the identical chipbreaker geometry and thickness of regular sized inserts to maintain the same cutting performance at a depth of cut up to 3.0 mm (0.12"). This expansion provides more cost-efficient solutions in steel turning applications, according to the company.

Major expansions have been made to the existing NS9530 uncoated cermet insert, GT9530 and AT9530 coated cermet insert and T9215 and T9225 CVD-coated carbide insert lines by increasing nose radii and chipbreaker-style options.

TS-style chipbreaker, which Tungaloy says is a chipbreaker for finishing processes with proven chip control at light cutting depths, is now available on cermet inserts, providing extended tool life and wear predictability for finish turning of steel parts.

Existing ZF- and ZM-style chipbreaker lines have also been expanded, increasing geometric options that provide better chip control in challenging finish profiling of intricate 3D surfaces. Along with new nose radii options, an expanded insert family of ISO-EcoTurn will further deliver cost-efficient, high-performing turning solutions.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

.png;maxWidth=300;quality=90)