Injection Mold Networking Software Application Reduces Mold Transfer Inefficiency

The Hub for Mold Transfer offered by RJG facilitates standardized processes, improves organizational efficiency and ensures proper mold and machine matching across global facilities.

Photo Credit: RJG

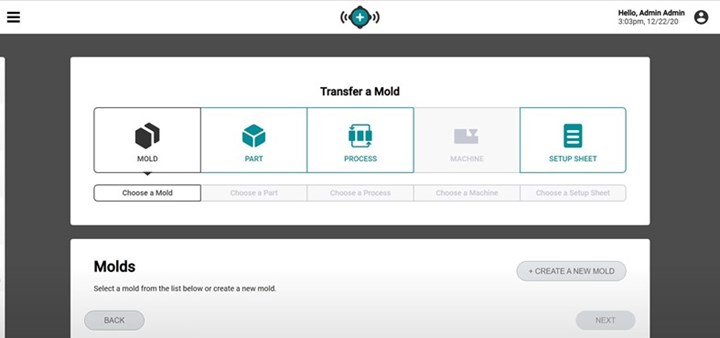

RJG’s injection mold networking software, The Hub, now has a new application available: The Hub for Mold Transfer.

The Hub connects RJG’s CoPilot process monitoring systems to a single interface, enabling users to access all plant information globally, make data-driven decisions, increase visibility, decrease liability and improve operational efficiency. Alternately, RJG says the Hub for Process Analytics enables users to access real-time data from anywhere, review and export reports, view job audit reports, replay historical data and more.

Moreover, the Hub for Mold Transfer is said to permit an easy transfer of molds by automatically generating machine-specific setup sheets, recommending compatible machines and providing a database to store and share part, mold and machine documentation across the organization. According to the company, this application significantly reduces the risk of damage and poor quality by ensuring proper mold and machine matching.

The Hub for Mold Transfer also features:

- Facility asset database for machines, molds, parts and materials

- Mold match recommendations for fit and capability

- Universal process sheet database

- Machine-specific setup sheet database

- Automatically generated, machine-specific setup sheets

- Revision history.

Related Content

-

Take Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

Simulation is a Process, Not Just Software

To reap the benefits of simulation, you must view it as a process requiring you to change the way you work in part and mold design.

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)