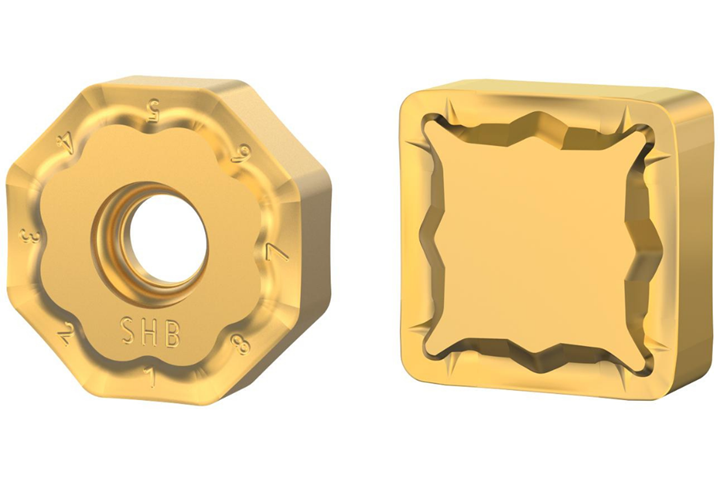

Indexable Milling Grades Achieve 30% Longer Tool Life

New Kennametal KCK20B and KCKP10 grades offer higher wear resistance without the need for insert change, increasing productivity in cast iron and compacted graphite cast iron machining.

In mold and die applications, process stability, high-surface quality and tool life are all key for optimal efficiency. This is why Kennametal has introduced the PVD-coated KCK20B and KCKP10 indexable milling grades for higher wear resistance, up to 30% longer tool life when machining cast iron and compacted graphite iron components and no rework needed. Both grades are said to offer higher productivity and consistent, repeatable performance during roughing, semi-finishing and finishing operations; the inserts also work well when profiling and copy milling cast iron and steels up to 45 HRC.

Gil Getz, product manager, Kennametal, points out that the new grades feature High-Power Impulse Magnetron Sputtering (High-PIMS) technology for a smoother insert surface and optimal layer adhesion for less flank wear — said to be one of the leading causes of insert failure. He notes that the new coating technology also increases cutting-edge strength, resulting in the ability to mill in a broad range of cast iron alloys — a material often used to manufacture large-sized parts, plates, spacers and bushings — including gray cast iron, ductile cast iron and compacted graphite cast iron.

In addition, KCK20B and KCKP10 are suitable for wet or dry cuts. These include rotor hubs used in windmills, pump housings, steering knuckles and gear housings for heavy equipment, and automotive components, such as crankshafts and cylinder heads.

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)