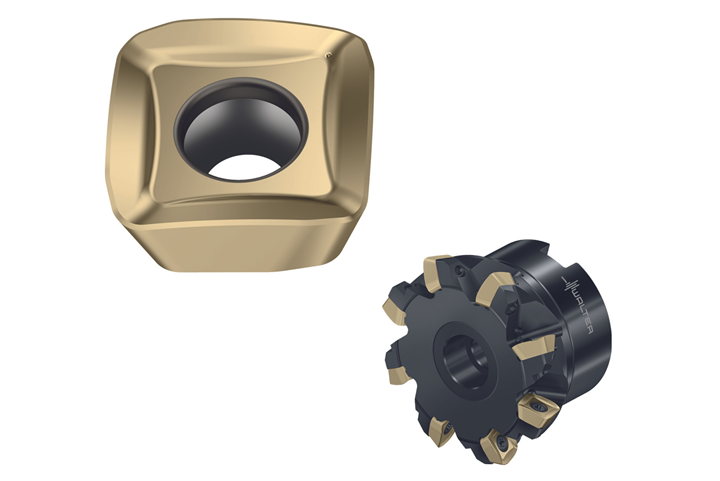

Indexable Insert Reduces Cost, Power Requirements For Demanding Machining Requirements

Walter’s universal system of indexable inserts for the M4002 high-feed milling cutter can machine steel, cast iron, stainless steel and difficult-to-cut materials.

Photo Credit: Walter USA

Walter USA reveals an SDMX indexable insert for its Walter M4002 high-feed milling cutter. Consequential to its highly positive geometries, the square positive, universal insert lowers power requirements. It is thick for maximum process reliability and provides four cutting edges per indexable insert with a curved cutting edge for complete stability.

There are two indexable insert sizes with facet—SDMX0904ZDR-E27 and SDMX1205ZDR-E27. The M4002 cutter provides a depth of cut of 1.5 or 2.0 mm and is available in diameters of 25-125 mm or 1-4" and is ideal for high-speed milling in steel, cast iron, stainless steel and materials with difficult cutting properties. Demanding machining in mold and die making and general machining are also applicable uses.

Related Content

-

Ejector Pin Selection Guide

A review of materials, treatments and coatings to help determine the proper pins for optimized plastic part ejection.

-

Forces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.