Flute End Mill Series Addition Focuses on Finishing Operations

Additions to M.A. Ford’s TuffCut 3D family of end mills takes finishing to the extreme to meet aerospace, medical, motorsport, and mold and die requirements.

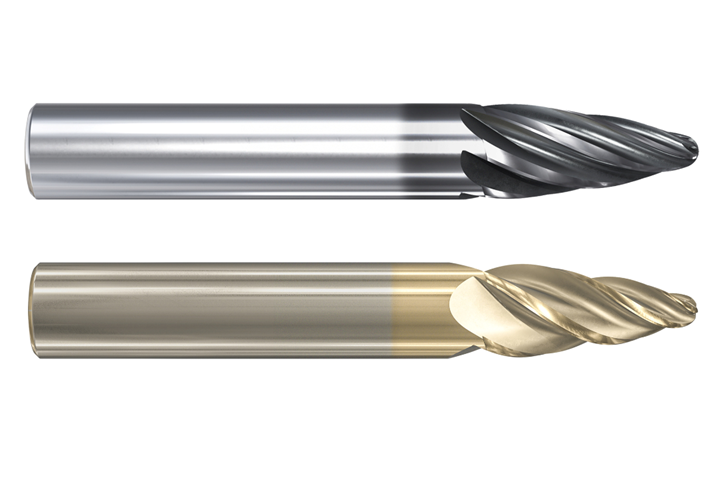

The M.A. Ford TuffCut 3D XFO and XFO-AL series tangential radius form enables high-accuracy finishing of large drafted/radiused surfaces and blended fillets with one cutting tool. The series is designed to machine with a large stepover during finishing and semi-finishing operations accurately and efficiently. With their tight tolerances and wide range of material suitability this cutting tool is best used in the aerospace, medical, motorsport, and mold and die industries.

The XFO series features four to six flutes, with metric sizes from 6 to 12 mm. An ALtima Q coating ensures optimal heat and wear resistance for increased tool life. Progressive helix and rake angles allow for smooth, vibration-free finishing along with enhanced edge preparation for strength and stability. The XFO’s material focus is in stainless steels, titanium and high-temp alloys which makes it suitable for in steels and hardened steels up to 50 HRC for moldmaking.

The XFO-AL series has three to four flutes, with metric sizes from 6 to 12 mm, and is coated with the company’s Fordlube coating for increased wear resistance and lubricity. An enhanced notch design, along with its high shear action, makes this an optimal cutting tool for aluminum machining.

For maximum benefits, a five-axis machine is most often required to effectively utilize the TuffCut 3D XFO and XFO-AL series, and sophisticated CAM software capable of driving circle segment tooling is required.

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Forces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.