Diamond-Coated End Mills for Machining Electrodes

Adding on to Crystallume’s Standard Premium and Lightning coatings is Stealth, the company’s thinnest diamond coating for highly detailed moldmaking work.

Share

Read Next

Crystallume, known for its chemical vapor deposition (CVD) diamond technology, features its three diamond-coated tool lines — Standard Premium, Lightning and Stealth — for machining the thinnest details in graphite electrodes.

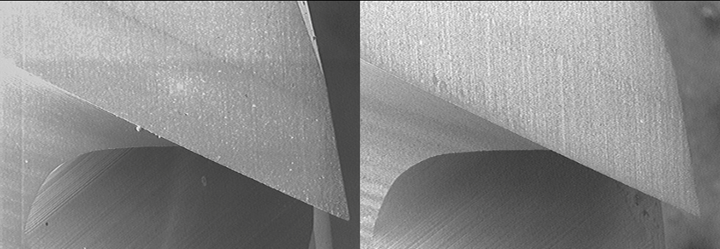

The company’s newest and thinnest diamond coating, Stealth, is only 2-3 µm thick, ensuring that tools with the coating have the sharpest solid diamond cutting edge available, according to the company. Depicted in the images above via scanning electron microscope is a cutting tool with the Stealth coating (left) and one without (right).

Four-flute Stealth end mill series are available, with a cutting diameter of 1/32 to ¼ and overall length of 1.5-4".

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Forces and Calculations Are Key to Sizing Core Pull Hydraulic Cylinders

To select the correct cylinder, consider both set and pull stroke positions and then calculate forces.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

.png;maxWidth=970;quality=90)