Cutting Tool Series Ups Mold and Die Machining Results

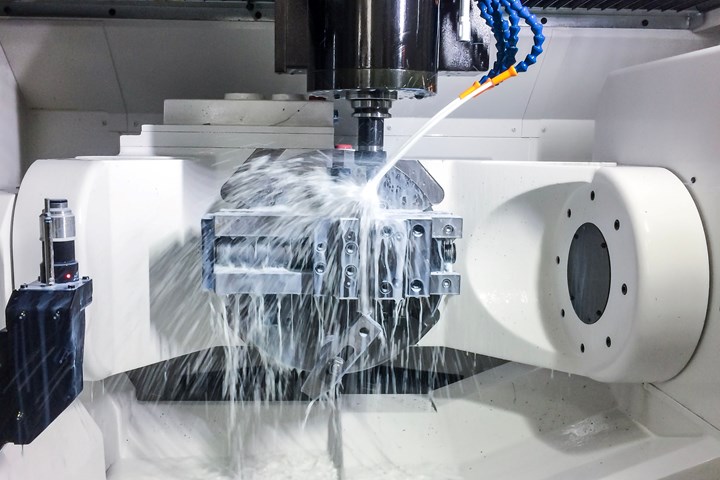

Precision, efficiency and quality finishes are achieved with Kyocera SGS Precision Tools’ three cutting tool lines, Turbo-Carb, Z-Carb MD, and Power-Carb.

Intricate components require exceptional precision. To meet the mold and die industry’s demands, Kyocera SGS Precision Tools highlights the Turbo-Carb, Z-Carb-MD and Power-Carb cutting tool series, each of which contributes to quality finishes and maximum value.

Engineered with a short flute length and rigid design, the Turbo-Carb series minimizes deflection, ensuring precision and accuracy. Its S-Gash Ball geometry effectively reduces load and heat generated during cutting, extending tool life. It is well suited for machining complex contoured shapes in hardened steels.

The Z-Carb-MD is designed with a negative rake, heavy core and higher helix, offering high strength and shearing capabilities. The unequal flute spacing disrupts cutting patterns, minimizing damaging harmonics. With enhanced corner geometry and tight tolerance corner radii, precision is said to be boosted.

The Power-Carb end mill specializes in trochoidal milling applications in hardened mold and die steels. This cutting tool excels in dry machining scenarios. With its short flute length and large core design, Power-Carb minimizes deflection for precise and accurate milling. Optimized edge strength is the result of extreme negative rake and eccentric relief.

These three tool series benefit from high performance and durability with the addition of the Ti-Namite-X coating, according to the company, which reduces edge wear by 66%, extends tool life by up to 70% and increases smoother surface finishes by 321%.

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Plastic Prototypes Using Silicone Rubber Molds

How-to, step-by-step instructions that take you from making the master pattern to making the mold and casting the plastic parts.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

.png;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)