Cavalier Tool & Manufacturing Emphasizes Onboarding Process for Plastic Injection Molding

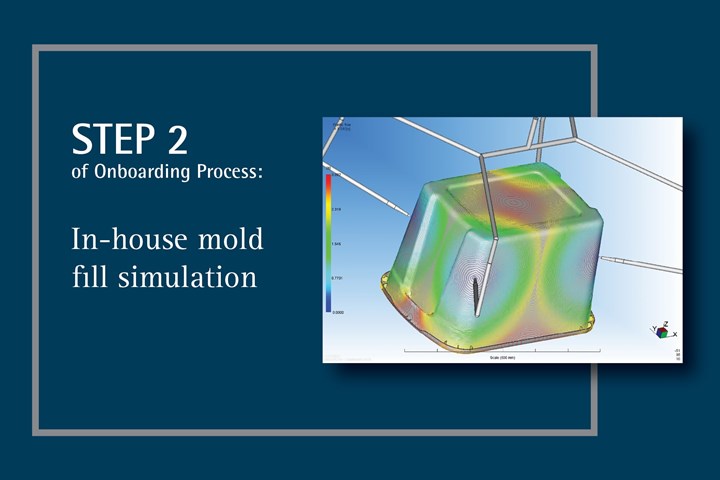

The global mold manufacturer’s three-step onboarding process covers part feasibility, flow simulation and commercial assessment for a 25% reduction in tool build time.

Photo Credit: Cavalier Tool & Manufacturing Ltd.

Cavalier Tool & Manufacturing, a global mold manufacturer and Amerimold 2021 exhibitor, emphasizes its exceptional customer service in plastic injection molding, which, simplified to a three-step onboarding process, is reportedly able to effectively reduce tool build time by up to 25%.

Step one is part feasibility. According to Cavalier, even if a user’s data is not final, its team will review the part with a toolmaker’s lens. Step two focuses on flow simulation. Cavalier runs mold filling simulations to provide valuable feedback for manifold configuration, gate location and press selection. Commercial assessment is covered in the last step when part optimization and tool design concepts have been completed. At this point, the company’s estimating group will revisit the proposed cost and timing and provide an accurate project quote.

Exhibitor: Cavalier Tool & Manufacturing Ltd.

Booth 235 (P)

Related Content

-

VIDEO: Explaining MoldMaking Versus Mold Manufacturing

To understand how training has been impacted we first need to understand the differences between a few key concepts. What is moldmaking vs. mold manufacturing? Who is a mold designer vs. a mold engineer?

-

MoldMaking Technology's Leadtime Leader Awards Competition Returns!

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards Competition is back!

-

Precision Custom Core Pins

Smith Enterprises highlights its wide range of custom core pins for high-cavitation molds.

.png;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)